For centuries, humans had exploited metals’ normal property to become stronger or harden when mechanically deformed. Eventually, they rooted in the motion of dislocations, mechanisms of metal hardening have remained in the crosshairs of sight of physical metallurgists for longer than a century.

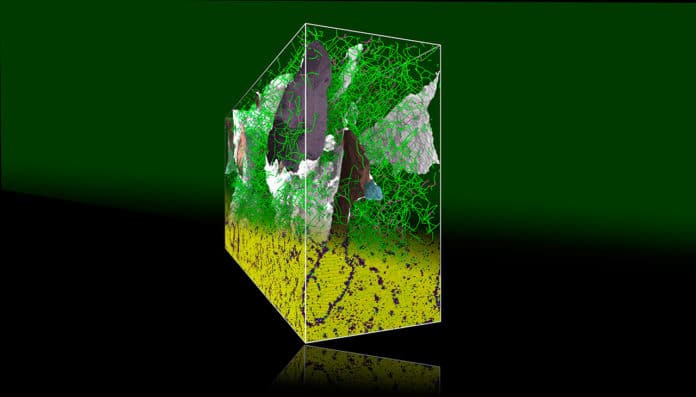

A research team Lawrence Livermore National Laboratory (LLNL), solves this mystery by taking it down to the atomistic level. They performed atomistic simulations at the limits of supercomputing sufficiently large to be statistically representative of macroscopic crystal plasticity yet fully resolved to examine the origins of metal hardening at its most fundamental level of atomic motion.

LLNL materials scientist Vasily Bulatov said, “We relied on a supercomputer to clarify what causes metal hardening. Instead of trying to derive hardening from the underlying mechanisms of dislocation behavior, which has been the aspiration of dislocation theory for decades, we performed ultra-large-scale computer simulations at a still more basic level—the motion of atoms that the crystal is made of.”

Scientists demonstrated that the notorious staged (inflection) hardening of metals is a direct outcome of crystal rotation under uni-axial straining. At chances with generally disparate and conflicting perspectives in the literature, specialists found that the essential systems of dislocation behavior are the same overall metal hardening phases.

Bulatov said, “In our simulations, we saw exactly how the motion of individual atoms translates into the motion of dislocations that combine to produce metal hardening.”

Journal Reference:

- Luis A. Zepeda-Ruiz et al. Atomistic insights into metal hardening, Nature Materials (2020). DOI: 10.1038/s41563-020-00815-1