Lightweight, easy and adaptable electronic frameworks are the way to cutting edge brilliant advances for military and also a customer and business applications.

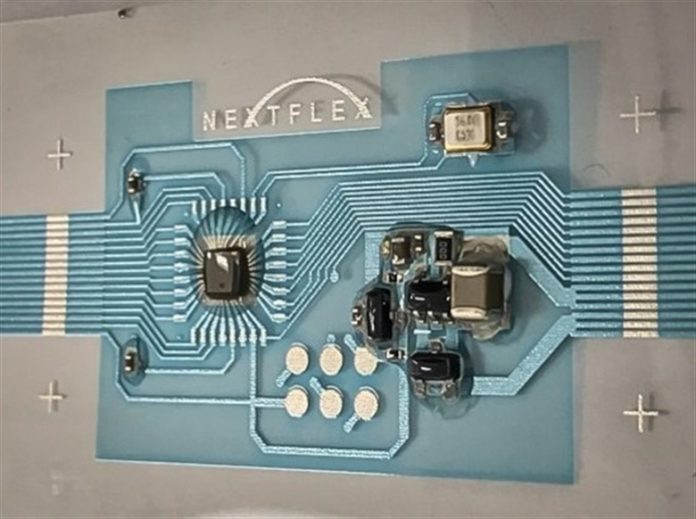

An Air Force Research Laboratory-drove venture in conjunction with NextFlex, America’s Flexible Hybrid Electronics Institute, has brought about the main ever, practical examples of adaptable Arduino circuit board frameworks made by utilizing an adaptable crossover gadgets fabricating process, setting the phase for savvy advancements for the web of things (IoT) and sensor applications like wearable gadgets.

Arduinos are microcontrollers, or incorporated circuits, that are programmable through open-source programming. While business gadgets commonly incorporate exclusive microcontrollers, Arduino can be utilized by anybody to rapidly model an electronic gadget.

The framing factor of electronic gadgets is regularly constrained by conventional microcontrollers, which are delicate and inflexible in configuration, entangling their reconciliation with more up to date gadgets that might be adaptable or bent in outline, for example, a smartwatch, or situated in a hard-to-get-to put, similar to a fuel tank sensor. The adaptable Arduino can empower fast advancement in adaptable and wearable gadgets for applications including observing hydration status, glucose levels, heart rate and that’s only the tip of the iceberg.

During the time spent building up the adaptable half and half gadget, the NextFlex group decreased the quantity of assembling process ventures by more than 60 percent and the heaviness of the circuit by 98 percent, at last expanding the conceivable outcomes for plan applications. This was accomplished by supplanting the customary circuit board with a thin, adaptable plastic sheet, wiping out the conventional microcontroller bundling, and actualizing computerized printing forms for circuit components. The elite of a conventional microcontroller circuit is kept up through this blend of surface-mounted and painted highlights.

Dr. Benjamin Leever, the AFRL Advanced Development Team leader, and NextFlex Government Chief Technology Officer said, “The possibilities for FHE (flexible hybrid electronics) technology are virtually limitless. Proving the manufacturability of this technology through an open-source platform will expand FHE’s reach even further by providing everyone from industrial product developers, to high school students, the opportunity to innovate on new electronics concepts.”

“As we look to innovation from non-traditional sources, the flex Arduino can enable inventors inside and outside the Air Force to quickly demonstrate new flexible electronics concepts. Moreover, the FHE manufacturing processes demonstrated by NextFlex in this project will be transformational for a number of Air Force applications. This technology may enable us to monitor the structural integrity of aircraft through sensors embedded in the wings or similarly monitor the real-time performance and health of an Airman through flexible sensor patches.”

The NextFlex team plays a major role to help accelerate innovation, enabling new technologies along with tremendous potential the Air Force.

Leever said, “We are pleased to have teamed with NextFlex on this project and look forward to the next steps in the optimization process. This is truly a momentous achievement for the FHE community.”