Generally, the Casting process is used to create concrete components. Yet, the shape required spots critical confinements on plan conceivable outcomes. 3D printing now gives new flexibility in forming.

Scientists at the Technical University of Munich (TUM) are exploring different avenues regarding different procedures, including particular authoritative. This innovation has made it workable out of the blue to make complicated, bionic structures from genuine cement.

3D technology now becomes an everyday technology in many industry segments. It enables a wide range of shapes at high levels of cost-efficiency, even in small batch sizes.

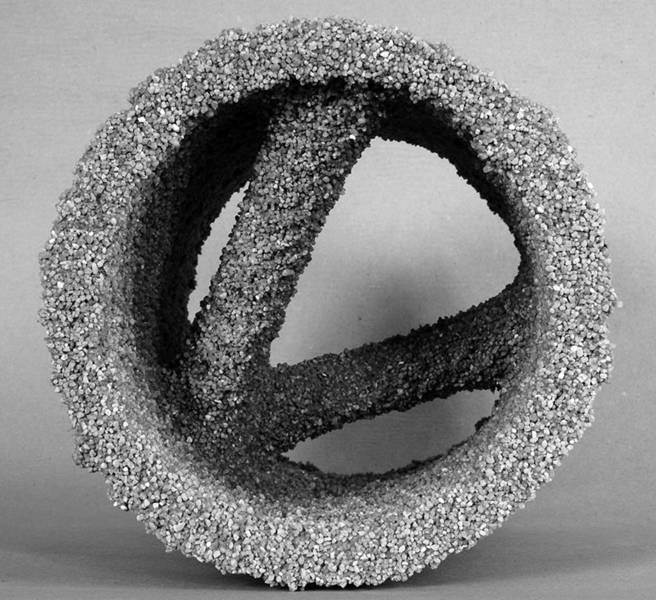

Scientists created a component as a prototype- a 20 centimeter high thin-walled concrete pipe whose interior contains intricate bracing which stabilizes the structure. The outline was propelled by the bone of a bird: Very thin and light, yet at the same time exceptionally steady.

The bionic part is in reality to a great degree strong. Material testing has demonstrated that these pipes can withstand powers of up to 50 Newtons for every square millimeter. This makes the written word similarly as steady as traditional caste concrete.

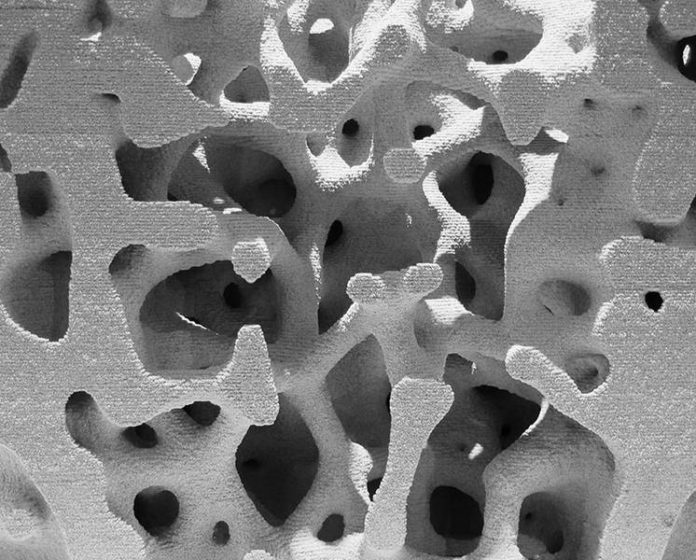

Scientists also used a novel technology to produce the pipe: selective binding. Through this, they drenched thin layers of sand with a mixture of cement and water at exactly those points at which the solid structure is to be created. When this mixture gets set, the surplus sand can be removed, leaving just the coveted solid structure.

To do so, scientists primarily build a selective binding unit. The over-dimensioned printer fills a whole lab room in the cellar at the Chair’s premises: Sand is dispersed utilizing a programmed disseminating framework.

A three-dimensional arrangement of tracks ensures the print head can be situated at any coveted point in the working space and a spout can apply a liquid to precisely the coveted focuses.

Scientists tinkered with the procedure for three long years: Success depends in addition to other things on the thickness of the layers, the grain size of the sand, the speed at which the print head moves and the choice of the correct spout.

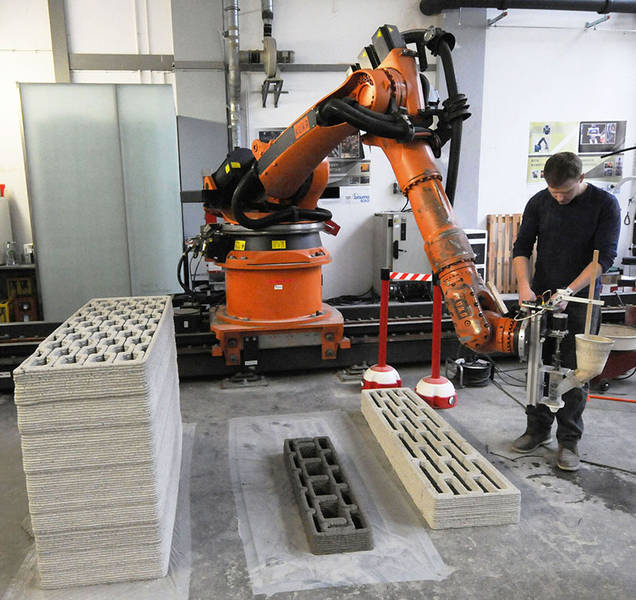

Another option is the expulsion technique, in which pre-blended cement can be utilized. Scientists investigated it and optimized this 3D printing method.

Henke said, “The advantage is primarily in the high construction speed. The selection of material components and formation of interior cavity structures make it possible to produce multi-functional components. For example, adding wood chips, which contain a large amount of air, provides integrated thermal insulation, protecting buildings from undercooling in the winter and overheating in the summer.”

Scientists conceived it and implemented an extrusion system to process the new lightweight wood-concrete- the mixture of cement, wood and water is pumped through a nozzle, creating strands of concrete as much as approximately 2 centimeters thick. They then mounted this nozzle on a computer-controlled robot arm that unequivocally puts the strands over each other to shape the coveted structure.

Henke said, “through this extrusion method, we were able to construct 1.5 meter wide and 1 meter high prototypes made of lightweight wood-concrete. This structure can be used as a design element or can be post-processed.”

Scientists noted, “The technology not only allows more versatile shaping but also more variety since each component can be individually designed without incurring any additional costs.”