There will soon be nothing that can’t be delivered with 3D printing. Be that as it may, the materials utilized for this procedure are still ‘dead issue’, for example, plastics or metals.

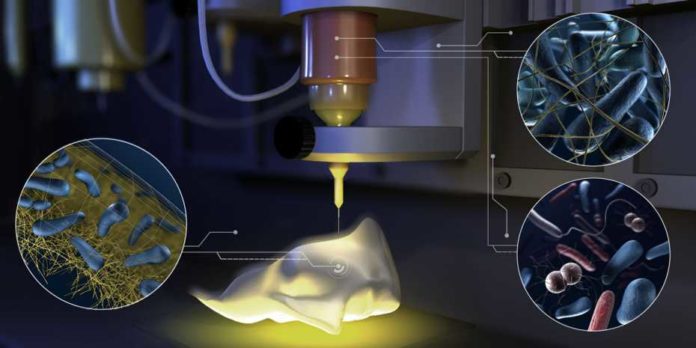

Now, scientists at ETH Zurich introduced a new 3D-printed platform that works using living matter.

The specialists built up a microbe containing ink that makes it conceivable to print little biochemical industrial facilities with specific properties, contingent upon which types of microscopic organisms the researchers put in the ink.

Scientists used the bacteria Pseudomonas putida and Acetobacter xylinum in their work. The former can separate the poisonous substance phenol, which is created on an amazing scale in the synthetic business, while the last secretes high-immaculateness nanocellulose. This bacterial cellulose alleviates torment, holds dampness and is steady, opening up potential applications in the various treatment.

This new 3D-printed platform offers numerous potential combinations. In a solitary pass, the researchers can utilize around four unique inks containing diverse types of microorganisms at various fixations so as to create objects showing a few properties.

The ink is composed of a biocompatible hydrogel that provides structure. The hydrogel itself is composed of hyaluronic acid, long-chain sugar molecules, and pyrogenic silica. The culture medium for the bacteria is mixed with the ink so that the bacteria have all the prerequisites for life. Using this hydrogel as a basis, the researchers can add bacteria to the desired “range of properties” and then print any three-dimensional structure they like.

Scientists dubbed this printing material as Flink. Flink stands for functional living ink.

Amid the advancement of the microscopic organisms containing hydrogel, the gel’s stream properties represented a specific test: the ink must be sufficiently liquid to be constrained through the weight spout.

The consistency of the ink additionally influences the microorganisms’ versatility. The stiffer the ink, the harder it is for them to move. In the event that the hydrogel is too firm, in any case, Acetobacter secretes less cellulose.

In the meantime, the printed objects must be sufficiently tough to help the heaviness of ensuing layers. In the event that they are excessively liquid, it isn’t conceivable, making it impossible to print stable structures, as these crumple under the weight applied to them.

Manuel Schaffner, first author of the study said, “The ink must be as vicious as toothpaste and have the consistency of Nivea hand cream.”

Co-author Patrick Rühs said, “Printing using bacteria-containing hydrogels has enormous potential, as there is such a wide range of useful bacteria out there.

“Most people only associate bacteria with diseases, but we actually couldn’t survive without bacteria.”