MIT scientists’ new work offers a possible starting point for novel approaches to biomaterials production that ease the environmental burden of forestry and agriculture. They have developed a new way to grow specific plant tissues, such as wood and fiber, in a lab.

Scientists tested their concept by growing structures made of wood-like cells from an initial sample of cells extracted from zinnia leaves.

Luis Fernando Velásquez-García, a principal scientist in MIT‘s Microsystems Technology Laboratories, said, “The way we get these materials hasn’t changed in centuries and is very inefficient. This is a real chance to bypass all that inefficiency.”

Ashley Beckwith, lead author and a Ph.D. student in mechanical engineering, said, “Can we be more strategic about what we’re getting out of our process? Can we get more yield for our inputs?”

“I wanted to find a more efficient way to use land and resources so that we could let more arable areas remain wild, or to remain lower production but allow for greater biodiversity. So, I brought plant production into the lab.”

Scientists grew wood-like plant tissue indoors- without soil or sunlight. They began with a zinnia plant, extracting live cells from its leaves. By culturing the cells in a liquid growth medium, they were able to metabolize and proliferate.

They then transferred the cells into a gel and “tuned” them. They cozed the cells to grow a rigid, wood-like structure using a mix of two plant hormones called auxin and cytokinin.

Variations of the level of these hormones within the gel, scientists were able to control the cells’ production of lignin, an organic polymer that lends wood its firmness.

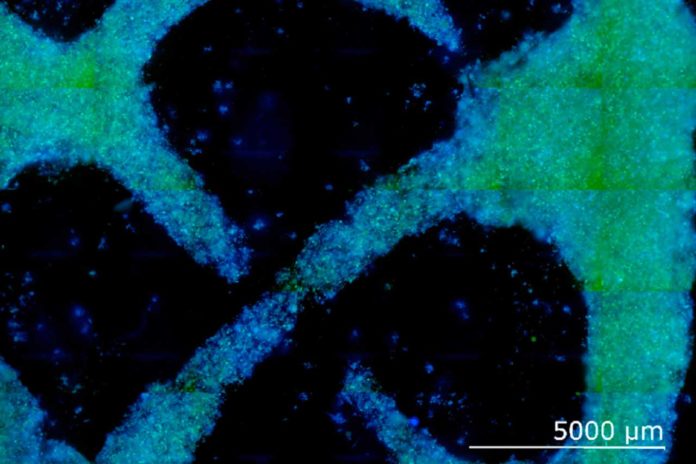

Beckwith said, “the cellular composition and structure of the final product using fluorescence microscopy. You can visually evaluate which cells are becoming lignified, and you can measure enlargement and elongation of cells.”

This procedure demonstrated that plant cells could be used in a controlled production process, resulting in a material optimized for a particular purpose.

Velásquez-García said, “The work extends our lab’s focus on microfabrication and additive manufacturing techniques like 3D printing. In this case, the plant cells themselves do the printing with the aid of the gel growth medium. Unlike an unstructured liquid medium, the gel acts as a scaffold for the cells to grow in a particular shape.”

“The idea is not only to tailor the properties of the material, but also to tailor the shape from conception.”

Although, the method is not market-ready yet. Scientists acknowledge it’s still early days for these lab-grown plant tissues — the team will keep fine-tuning the controls, like hormone levels and pH of the gel, that give rise to the final material’s properties.

David Stern, a plant biologist at Cornell University who was not involved with the research, said, “The question is whether the technology can scale and be competitive on an economic or lifecycle basis. Scaling up this approach “would take significant financial and intellectual investment,” likely from both government and private sources. Stern also points to tradeoffs in bringing pieces of forestry and agriculture into the lab.”

“Agriculture uses the sun’s energy through photosynthesis, and — except in irrigated lands — natural rainfall. It does not require buildings, heat, or artificial light.”

This research was funded, in part, by the Draper Fellow Program.

Journal Reference:

- Ashley L.Beckwith et al. Tunable plant-based materials via in vitro cell culture using a Zinnia elegant model. DOI: 10.1016/j.jclepro.2020.125571