An international tea of scientists led by UNIST has recently discovered a novel approach for creating synthetic graphite with well-oriented crystallites. The discovery offers an approach to realize single crystal graphite films, perhaps in combination with established techniques, such as stress recrystallization.

Most materials including graphite comprise of little and randomly situated precious stones that are interconnected to make up the mass material. In graphite, no strategy exists to make vast single-gems, and profoundly situated examples (“exceptionally arranged pyrolytic graphite”, HOPG) that are of significance in research applications have required an expensive mix of extremely high temperatures and pressures to fabricate.

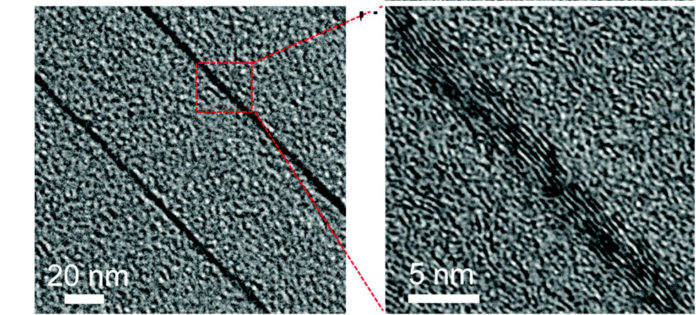

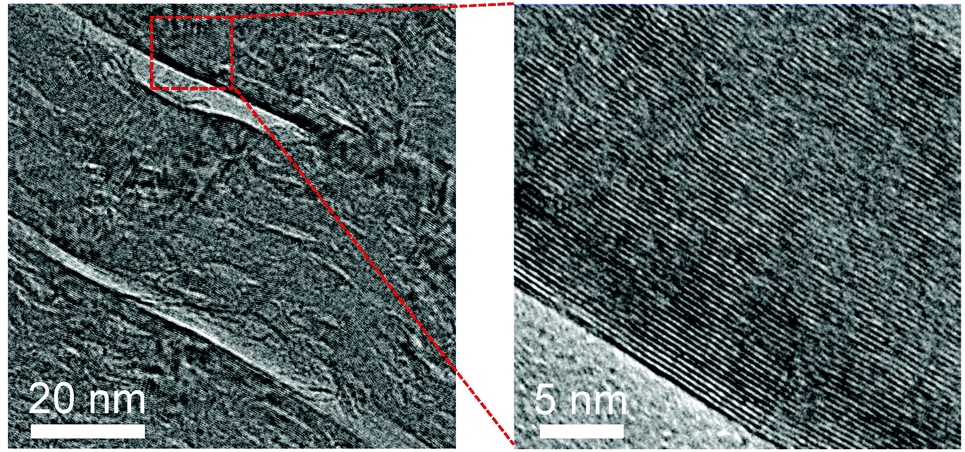

The team incorporated a layer of near-perfect single-crystal graphene (grown separately and transferred) in the carbon precursor before heating. Graphite was found to form with a preferred orientation adjacent to this single crystal graphene when the polymer carbonized and then graphitized.

Benjamin V. Cunning said, “What we observe is a templating effect. When the carbon atoms of the precursor are heated, they have more energy to move around and those near to the graphene layer ‘copy’ the arrangement of the atoms in the graphene—which has a perfect hexagonal arrangement of its carbon atoms. When the temperatures increase even further a kind of “domino effect” takes place where each layer is copying the arrangement from the layer before resulting in a well-oriented graphite film.”

Dr. Bin Wang, IBS Research fellow, highlighted the ability to make films with large lateral sizes. “The only restriction to how large these films can be made is currently how large the graphene can be grown, and we currently can grow single-crystal graphene 4cm x 8cm, but improvements will eventually allow much larger sizes.”

Director Tae Joo Shin said, “The improvement in grain orientation that we observed from incorporating graphene was quite interesting.”

Single crystal graphite is famously difficult to synthesize. It can survive for quite a while even at temperatures near 4000 °C so settled strategies for creating single crystals (working extremely near such a high temperature, for instance) can’t be connected to making graphite. Making all around situated movies may be the initial step that could result in inevitably accomplishing singly crystal graphite.

Professor Rodney S. Ruoff said, “Given the exceptional importance of graphite in many applications and its very large scale production but essentially as only a flake-like material, we are very interested in exploring alternative approaches in the hope that one day we might be able to achieve large-scale single crystal graphite films.”

The research has been published in the January 24, 2019 issue of Materials Horizons.