Scientists demonstrated a new technique for 3D printing materials that involves stainless steel to achieve exception levels of both strength and ductility when compared to counterparts from more conventional processes.

The examination is in opposition to the skepticism around the capacity to make solid and flexible metals through 3D printing, and thusly the revelation is critical to advancing the innovation for the assembling of overwhelming obligation parts.

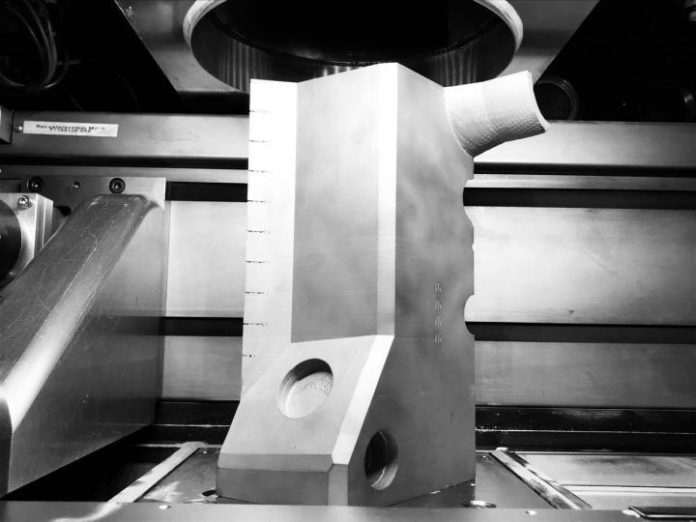

3D printing has for quite some time been perceived as an innovation which can possibly change our method for assembling, enabling us to quickly develop objects with complex and tweaked geometries.

With the quickening improvement of the innovation as of late, 3D printing, particularly metal 3D printing, is rapidly advancing toward across the board mechanical application.

With the quickening improvement of the innovation as of late, 3D printing, particularly metal 3D printing, is rapidly advancing toward across the board mechanical application.

Dr. Leifeng Liu, who is the main participant of the project said, “Strength and ductility are natural enemies of one another, most methods developed to strengthen metals consequently reduce ductility.”

“The 3D printing technique is known to produce objects with previously inaccessible shapes, and our work shows that it also provides the possibility to produce the next generation of structural alloys with significant improvements in both strength and ductility.”

Because of ultrafast cooling rate, scientists were able to perceive range from 1000oC per second to 100 million oC per second. This was literally not possible in bulk metal production process until the emergence of 3D printing.

Dr. Liu continued, “This work gives researchers a brand new tool to design new alloy systems with ultra-mechanical properties. It also helps metal 3D printing to gain access to the field where high mechanical properties are required like structural parts in aerospace and automotive industry.”

Metals that are chilled off so rapidly result in an alleged non-harmony state, taking into consideration some astounding microstructures like the sub-smaller scale measured disengagement arrange – which was uncovered in this paper to be the primary reason of the enhanced mechanical properties.