Solar cell plays an essential role in boosting solar power generation. But, still, scientists face limitations in scaling up this technology. For example, cost and effectiveness. Scientists from MIT in collaboration with the Masdar Institute of Science and Technology might have found a solution to this problem. Scientists have developed a new solar cell called step cell. This solar cell combines two different layers of sunlight-absorbing material to harvest a broader range of the sun’s energy.

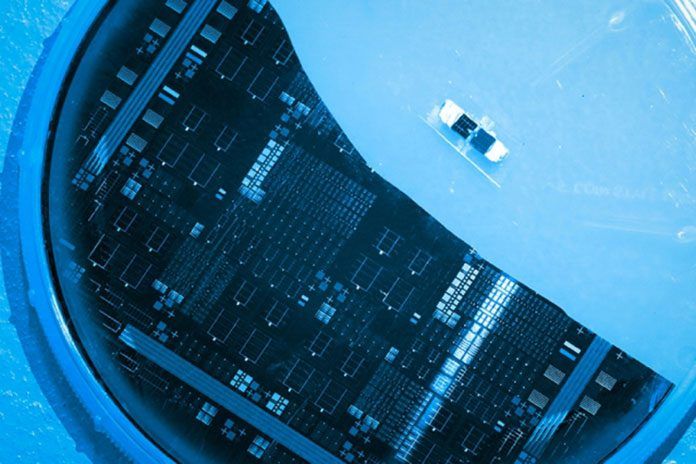

Scientists called it as step cell because the two layers are arranged in a stepwise fashion. The lower layer is projecting out below the upper layer, in order to expose both layers to incoming sunlight. This type of solar cell is expensive to fabricate. Thus, scientists used new, low-cost fabrication process.

According to scientists, this new step cell has a practical efficiency of 35% and theoretical efficiency is above 40%.

To absorb more sun’s higher energy photons, scientists have used unique semiconductor material. For example, gallium arsenide and gallium phosphide. This semiconductor has higher efficiency as compared to silicon. (Generally, silicon is use in conventional silicon crystalline solar cells for over a decade. It is considered as cheap to manufacture.)

This new semiconductor material is made by layering different semiconductor materials on top of each other. Scientists then adjust those layer. Thus, each layer absorbs different slice of electromagnetic spectrum. This new solar cell can be manufactured at a fraction of the cost. This is because the main equipment is manufactured on a substrate that can be reuse.

Silicon layer is reveal as a bottom step. The intentional design allows upper layer to absorb high energy photons by leaving the bottom silicon layer free to absorb lower-energy photons.

Sabina Abdul Hadi, a Ph.D. student at Masdar Institute, said, “We realize that when the top gallium arsenide phosphide layer completely covers the bottom silicon layer, the lower-energy photons absorbed by the silicon germanium (SiGe). SiGe, the substrate on which the gallium arsenide phosphide grown. Thus the solar cell had a much lower efficiency. By etching away the top layer and revealing some of the silicon layers, we were able to increase the efficiency considerably.”

Nayfeh explains, “Gallium arsenide phosphide (GaAsP) cannot be grown directly on silicon. This is because its crystal lattices differ considerably from silicons. Thus the silicon crystals become degraded. That’s why we grew the gallium arsenide phosphide on the silicon germanium. It provides a more stable base.”

The problem with the silicon germanium under the GaAsP layer is that SiGe absorbs the lower-energy light waves before it reaches the bottom silicon layer. SiGe does not convert these low-energy light waves into the current.

Nayfeh said, “To get around the optical problem poses by the silicon germanium, we developed the idea of the step cell. This allows us to leverage the different energy absorption bands of gallium arsenide phosphate and silicon.”

In step cell, the SiGe template removed and reused. It creates a solar cell in which GaAsP cell tiles are directly on top of a silicon cell.

Fitzgerald explains the future low-cost fabrication process. He said, “We grew the gallium arsenide phosphide on top of the silicon germanium. Then we designed it in the optimized geometric configuration and bonded to a silicon cell. Then we etched through the designed channels and lifted off the silicon germanium alloys on silicon. What remains then, is a high-efficiency tandem solar cell and a silicon germanium template, ready to be reused.”

“Adding the layer of gallium arsenide phosphide can increase the effectiveness of solar cell. But because of the unique ability to etch away the silicon germanium and reuse it, the cost is kept as low. Because you can amortize that silicon germanium cost over the course of manufacturing many cells,” he added.

He believes that this solar cell will fit well in the gap of solar PV market, between the super high-efficiency and low-efficiency industrial applications. If the volume increases in this market gap, the fabrication costs might decrease even further over time.

Nayfeh said, “This highlight the valuable role that research and international collaboration plays in developing a commercially-relevant technology-based innovation. It is a perfect demonstration of how a research idea can transform into an entrepreneurial reality.”