The mechanisms for removing emulsified oil from water are complex because of the deformability and potential for coalescence and break-up of the oil droplets. Now, for the first time, MIT scientists have developed a new imaging technique that could provide a tool for developing better membrane materials that can resist or prevent fouling.

Petroleum refining unavoidably generates large volumes of oily wastewater. The environmentally acceptable disposal of oily wastewater is a current challenge to the petroleum industry. Nowadays, more attention has been focused on the treatment techniques of oily wastewater. Therefore, oily wastewater treatment has become an urgent problem.

Methods of removing oily contaminants vary, depending on the relative amounts of oil and water and the sizes of the oil droplets. When the oil is emulsified, the most efficient cleanup method is the use of membranes that filter out the tiny oil droplets, but these membranes quickly get fouled by the droplets and require time-consuming cleaning.

Be that as it may, the fouling procedure is difficult to observe, making it difficult to evaluate the relative advantages of various materials and architectures for the membranes themselves.

Professor of chemical engineering Gregory Rutledge said, “These filtration membranes tend to be very hard to look inside of. There’s a lot of effort to develop new types of membranes, but when they get put in service, you want to see how they interact with the contaminated water, and they don’t lend themselves to easy examination. They are usually designed to pack in as much membrane area as possible, and being able to look inside is very hard.”

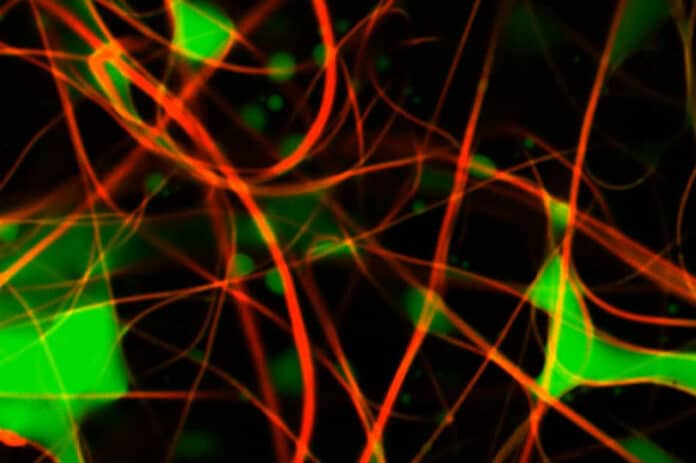

To develop this method, scientists used confocal laser scanning microscopy, a technique in which two lasers are scanned across the material, and at the point where the two beams cross, a material marked with a fluorescent dye will glow. They also introduced two fluorescent dyes, one to mark the oily material in the fluid, the other to mark the fibers in the filtration membrane.

Doing this enabled scientists to scan the material to its depth and build a 3D visualization of oil droplets on electrospun fiber microfiltration membranes after a period of membrane-based separation of oil-in-water emulsions.

Rutledge explains said, “The basic method has been used in biological research, to observe cells and proteins within a sample, but it has not been applied much to studying membrane materials, and never with both the oil and the fibers labeled. In this case, the researchers are observing droplets that range in size from about 10 to 20 microns (millionths of a meter), down to a few hundred nanometers.”

“Until now, methods for imaging pore spaces in membranes were pretty crude. For the most part, the pore characteristics were inferred by measuring flow rates and pressure changes through the material, giving no direct information about how the oily material actually builds up in the pores. With the new process, now you can actually measure the geometry, and build a three-dimensional model and characterize the material in some detail. So what’s new now is that we can really look at how separation takes place in these membranes.”

“By doing so, and by testing the effects using different materials and different arrangements of the fibers, this should give us a better understanding of what fouling really is.”

“The new observational method has clear applications for engineers trying to design better filtration systems, but it also can be used for research on the basic science of how mixed fluids interact. Now we can begin to think about some fundamental science on the interaction between two-phase liquid flows and porous media. Now, you can develop some detailed models of the process.”

“And the detailed information about how different structures or chemistries perform could make it easier to engineer specific kinds of membranes for different applications, depending on the types of contaminants to be removed, the typical sizes of the droplets in these contaminants, and so on. In designing membranes, it’s not a one-size-fits-all. Potentially you can have different types of membranes for different effluents.”

Rutledge said, “The method could also be used to observe the separation of different kinds of mixtures, such as solid particles in a liquid, or a reverse situation where the oil is dominant and the membrane is used to filter out water droplets, such as in a fuel filtration system.”

William J. Koros, the Roberto C. Goizueta Chair for Excellence in Chemical Engineering and GRA Eminent Scholar in Membranes at the Georgia Institute of Technology, said, “When I read his paper in depth, I was impressed by Greg’s way of using 3-D imaging to understand the complex fouling process in membranes used for oil-water emulsions.”

The new work is described in the journal ACS Applied Materials and Interfaces, in a paper by MIT graduate students Yi-Min Lin and Chen Song and professor of chemical engineering Gregory Rutledge.

Journal Reference

- Yi-Min Lin, Chen Song, and Gregory C. Rutledge*. Direct Three-Dimensional Visualization of Membrane Fouling by Confocal Laser Scanning Microscopy. ACS Appl. Mater. Interfaces 2019, 11, 18, 17001–17008. April 29, 2019 DOI: 10.1021/acsami.9b01770