Few years ago, scientists have found a unique use of waste cooking oil. This time, scientists came up with a new idea. Australian scientists have created a new material from cooking oil.

This time, scientists have transformed cooking oil into wonder material graphene. This graphene material is capable of making new electronics. It also can create more efficient photovoltaic cells.

Scientists called it as ‘GraphAir’ technology. The material is created by heating soybean oil in a tube furnace for about 30 minutes. This heating process causes graphene to decompose into carbon building blocks.

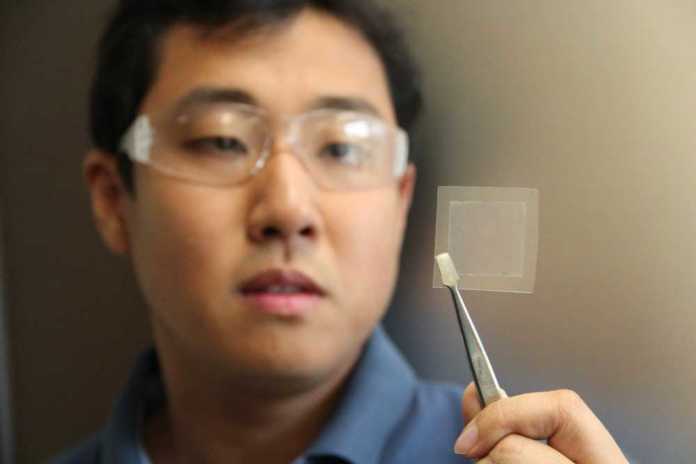

After that, the carbon is cooled on a nickel foil. It diffuses into a thin rectangle of graphene that’s just 1 nanometre thick.

The mindblowing property of this material that it is 200 times more stronger than steel. In addition, it is amazingly harder than diamond and also incredibly flexible.

Due to some limitations, graphene material needs to produce in a vacuum at intense heat using purified ingredients. But, this process makes it expensive to produce.

But scientists created this graphene material in normal air condition by only using cheap soybean oil.

Scientist Zhao Jun Han said, “This ambient-air process for graphene fabrication is fast, simple, safe, potentially scalable, and integration-friendly.”

“We expect that this new technology will reduce the cost of graphene production. It will improve the uptake in new applications.”

According to scientists, this technology offers a more sustainable option for recycling waste cooking oil.

A scientist, Dong Han Seo said, “We can now recycle waste oils that transform them into something useful after it discarded as waste.”

“The question now is whether this new technique can be scaled up – finding a cheaper way to make graphene is awesome. But the graphene film produced so far was only 5 cm (1.9 inches) by 2 cm (0.8 inches) in size. The largest film we can make using the technique right now is around the size of a credit card.”

Scientists are now looking for scaling up this technique economically. However, they have sealed it inside a furnace tube, to create and handle metre-sized films. So they are finding commercial partners to pursue this goal.