In a progression of examinations directed a month ago, Cambridge analysts experienced weightlessness testing graphene’s application in space.

Acting as a major aspect of a joint effort between the Graphene Flagship and the European Space Agency, scientists from the Cambridge Graphene Center tried graphene in microgravity conditions out of the blue while on board an illustrative flight – frequently alluded to as the ‘regurgitation comet’. The investigations they led were intended to test graphene’s potential in cooling frameworks for satellites.

“One of graphene’s potential uses, perceived at an opportune time, is space applications, and this is the first occasion when that graphene has been tried in space-like applications,” said Professor Andrea Ferrari, who is Director of the Cambridge Graphene Center, and in addition Science and Technology Officer and Chair of the Management Panel for the Graphene Flagship.

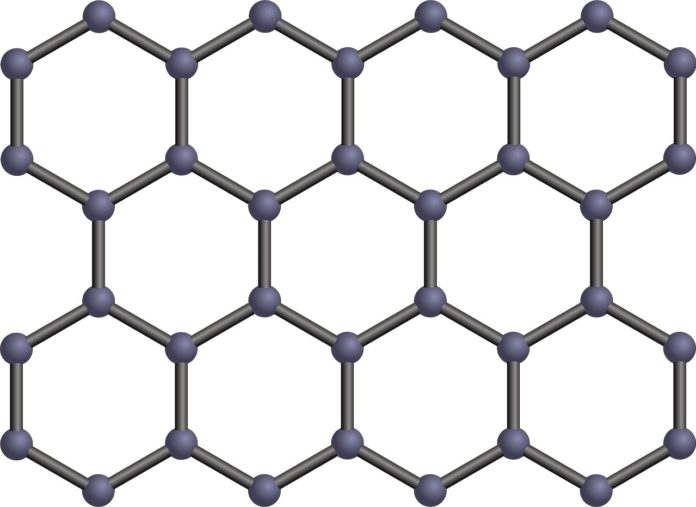

Graphene – a type of carbon only a solitary molecule thick – has a novel mix of properties that make it helpful for applications from adaptable gadgets and quick information correspondence, to improved basic materials and water medicines. It is exceptionally electrically and thermally conductive, and additionally solid and adaptable.

In this investigation, the specialists expected to enhance the execution of cooling frameworks being used in satellites, making utilization of graphene’s great warm properties. “We are utilizing graphene in what are called circle warm pipes. These are pumps that move liquid without the requirement for any mechanical parts, so there is no wear and tear, which is essential for space applications,” said Ferrari.

“We are going for an expanded lifetime and an enhanced self-rule of the satellites and space tests,” said Dr. Marco Molina, Chief Technical Officer of the Space line of business at industry accomplice Leonardo. “By including graphene, we will have a more solid circle warm pipe that can work independently in space.”

In a circle warm pipe, dissipation and buildup of a liquid are utilized to transport warm from hot electronic frameworks out into space. The weight of the dissipation buildup pushes powers liquid through the shut frameworks, giving constant cooling.

The primary component of the circle warm pipe is the metallic wick, where the liquid vanishes into gas. In these analyses, the metallic wick was covered in graphene, enhancing the effectiveness of the warmth pipe in two ways. Right off the bat, graphene’s magnificent warm properties enhance the warmth exchange from the hot frameworks into the wick. Also, the permeable structure of the graphene covering expands the communication of the wick with the liquid and enhances the slender weight, which means the fluid can course through the wick speedier.

Subsequent to promising outcomes in research facility tests, the graphene-covered wicks were tried in space-like conditions installed a Zero-G allegorical flight. To make weightlessness, the plane experiences a progression of explanatory moves, making up to 23 seconds of weightlessness in each move.

“It was really a superb ordeal to feel weightlessness, yet additionally the hyper-gravity minutes in the plane. I was exceptionally energized yet in the meantime somewhat apprehensive. I couldn’t rest the prior night,” said Dr. Yarjan Samad, a Research Associate at the Cambridge Graphene Center.

Amid the flight, the graphene-covered wicks again exhibited brilliant execution, with more productive warmth and liquid exchange contrasted with the untreated wicks. In light of these outcomes, the analysts are proceeding to create and improve the coatings for applications in genuine space conditions. “The following stage will be to begin taking a shot at a model that could go either on a satellite or on the space station,” said Ferrari.

The exploration was upheld by the Graphene Flagship and the European Space Agency, as a joint effort between scientists from Université Libre de Bruxelles, Belgium; the University of Cambridge, UK; the National Research Council of Italy (CNR), Italy; and industry accomplice Leonardo Spa, Italy.