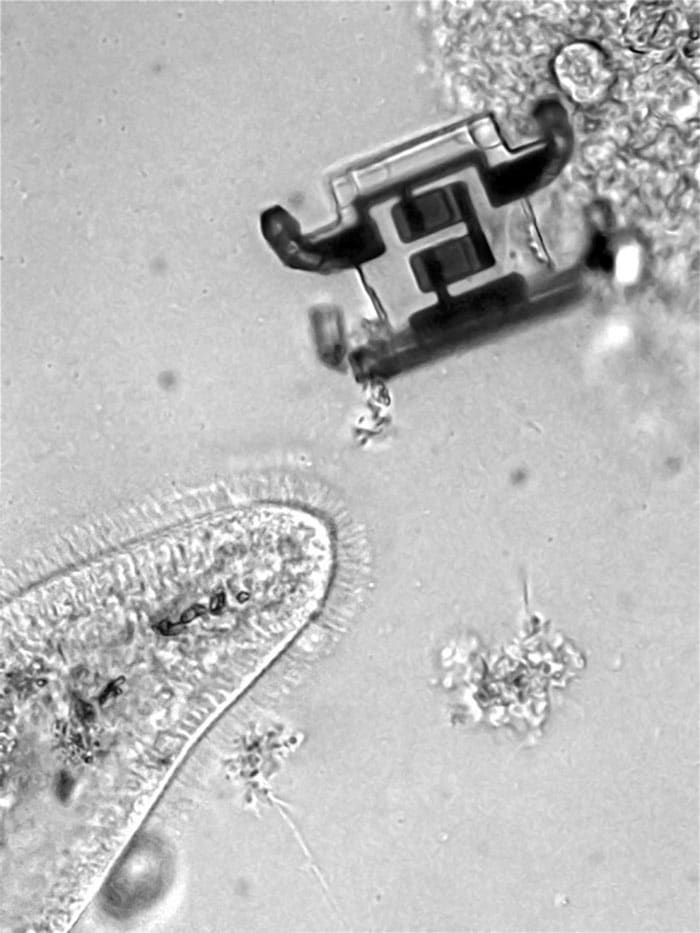

The rapidly evolving field of microscopic robotics offers tiny robots that are smaller than the resolution limit of human vision. These robots can explore new environments closer to home, including the human body, at the fundamental scale of biology – the cell.

Researchers from Cornell and the University of Pennsylvania have built microscopic robots that can be controlled and made to walk by flashing laser pulses at different photovoltaics. Roughly the size of paramecium, the robot provides a template for building even more complex versions that utilize silicon-based intelligence. It can be mass-produced, and may someday travel through human tissue and blood, delivering drugs.

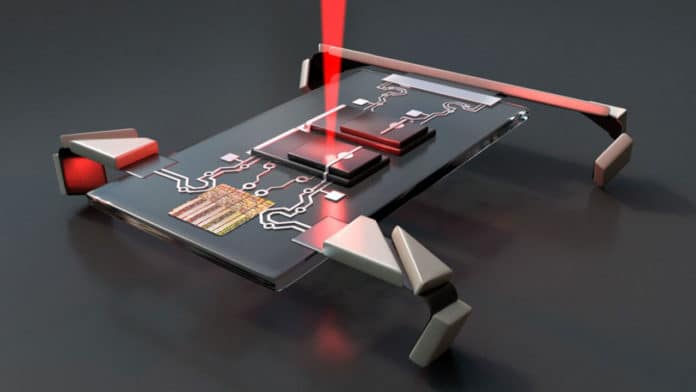

The robots themselves are only 5 microns thick, 40 microns wide, and 40 to 70 microns long, depending on the design. Each microscopic robot consists of a simple circuit made from silicon photovoltaics – essentially the torso and brain – and four electrochemical actuators that function as legs.

The legs are made from strips of platinum only a few dozen atoms thick, capped on one side by a thin layer of inert titanium and polymer panels on top of the strips. When platinum is exposed to an electric charge, the negatively charged ions from the surrounding chemical solution are absorbed onto the platinum surface, neutralizing the charge. These ions force the exposed platinum to expand, making the strip bend. The ultra-thinness of the strips enables the material to bend sharply without breaking.

To encourage the robot to actually move, the researchers flashed laser pulses at different photovoltaics, each of which charges up a separate set of legs. By alternating the lasers back and forth between the front and back photovoltaics, the robots can crawl.

These robots operate on a voltage of just 200 millivolts and power of 10 nanowatts while remaining strong and robust for their size. Because they are manufactured using standard lithographic processes, they can be developed in parallel. Moreover, they are very small – about 1 million of these robots can fit on a 4-inch silicon wafer.

“While these robots are primitive in their function – they’re not very fast, they don’t have a lot of computational capability – the innovations that we made to make them compatible with standard microchip fabrication open the door to making these microscopic robots smart, fast and mass-producible,” said Itai Cohen, one of the researchers on the study. “This is really just the first shot across the bow that, hey, we can do electronic integration on a tiny robot.”

Researchers are now exploring ways to soup up these microscopic robots with more complex electronics and capabilities. These improvements could one day result in swarms of microscopic robots crawling through and restructuring materials, or suturing blood vessels, or being dispatched en masse to probe large swaths of the human brain.

Journal reference:

- Electronically integrated, mass-manufactured, microscopic robots. DOI: 10.1038/s41586-020-2626-9