In 2010, there was a Catastrophic explosion and blowout occurred in the Deepwater Horizon oil rig. This was the worst oil spill in the history of the petroleum industry. The operators found a 125-ton containment dome over the broken wellhead. There was an icy mixture of frozen water and methane, called a methane clathrate inside the dome. Due to low temperatures and high pressure near the seafloor, the slushy mix built up inside the containment dome and causes pipeline clogging that preventing the slushy mix from redirecting the flow.

If it hadn’t been for that methane clathrate, the containment might have worked. That may be prevented four months of unabated leakage and widespread ecological devastation.

Now, MIT researchers have found a solution to pipeline clogging by developing a coating for the pipes. According to them, the coating prevents such a disastrous outcome, prevent blockages inside oil and gas pipelines and even pipeline rupture from a buildup of pressure.

Scientists approach was to develop coatings for containers that prevent the contents from sticking to the container walls. In this system, instead of applying lubricant to the surface, scientists used a liquid that’s in the environment itself.

The key characteristic of clathrate formation is the presence of water as long as the water can be kept away from the pipe wall to stop clathrate buildup. And the liquid hydrocarbons present in the petroleum, as long as they cling to the wall. The chemical affinity of the surface coating can effectively keep that water away

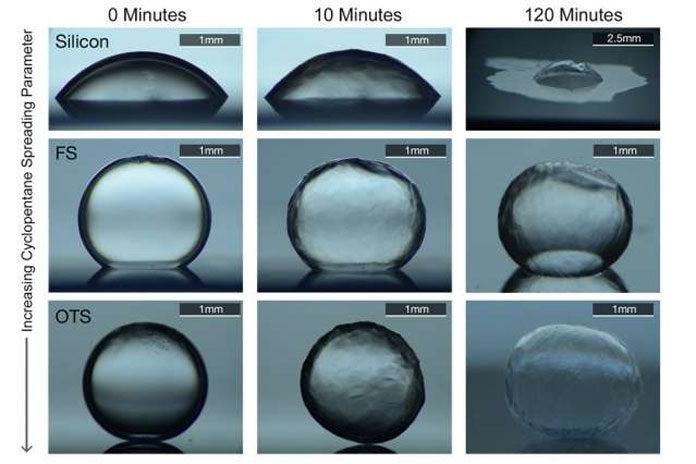

This newly developed pipe coating consists a layer of a material that promotes spreading of a water-barrier layer along the pipe’s inner surface. The layer that acts as a barrier for the adhesion of any ice particles or water droplets to the wall. Thus, it stops the buildup of clathrates that could slow or block the flow.

Associate professor of mechanical engineering Kripa Varanasi said, “Existing prevention measures, known as flow assurance measures, are expensive or environmentally unfriendly. Currently, the use of those measures runs into the hundreds of millions of dollars every year. Without those measures, hydrates can build up so that they reduce the flow rate, which can reduce revenues, and if they create blockages then that “can lead to catastrophic failure.”

It’s a major problem for the industry, for both safety and reliability.

As compare to previous methods, this method is completely passive. Once it is placed in the required position, it does not need any additional material.

The layer works by attracting liquid hydrocarbons that are already present in the flowing petroleum, creating a thin surface layer that naturally repels water. This prevents the ices from ever attaching to the wall in the first place.

Lead Author Arindam Das said, “Because methane hydrates themselves are abundant in many locations such as continental shelves. They have a huge new potential fuel source if methods can be devised to extract them. The reserves themselves substantially overshadow all known reserves of oil and natural gas on land and in deep water.”

But according to recent graduates Taylor Farnham, “Such deposits would be even more vulnerable to freezing and plug formation. Preventing these icy buildups depends critically on stopping the very first particles of clathrate from adhering to the pipe. Once they attach, they attract other particles” of clathrate, and the buildup takes off rapidly.”

The team said, “If the oil in the pipeline is made to spread more readily on the surface, then it forms a barrier film between the water and the wall. In lab tests, which used a proxy chemical for the methane, the system performed very effectively. We didn’t see any hydrates adhering to the substrates.”