We all have chewed chewing gums many times. Although, it helps to improve concentration and memory. A study also suggested that chewing gums boost our mental performance. There are various benefits of chewing gums including it combats Stress and Anxiety. After chewing, we usually throw it out and it gets waste.

Gum does not biodegrade. Waste bubble gum causes the major bad environmental impact. So, to recycle the waste gum, a company from London have covered gum into a raw material. The company degraded gum for commercial-grade thermoplastic elastomers, or TPEs, to make rain boots, smartphone covers, and other products.

The company Gumdrop Ltd. claims to be the first company in the world to collect, process, and recycle waste chewing gum. It is founded by Anna Bullus.

The used gum is not picked up by stepping on it in shopping mall’s parking lots or other public places. Instead, it is collected largely from the gum industry and consumer sources, thus diverting it from landfills and the undersides of desks and chairs. Then it gets converted into compounds from the waste stream.

According to engineers, the challenge of creating and manufacturing techniques for a new type of raw material consistently meet the requirements of specific applications. For example, elasticity, compression set, tensile, and other mechanical properties, as well as processability.

Stef Hordijk, a senior market manager said, “We assembled a multi-disciplinary team drawing on our capabilities for materials analysis, process engineering, and manufacturing. The team addressed basic considerations such as feeding it into our equipment, formulating compound recipes using this unique raw material, determining optimal compounding process parameters, and other issues posed by such an unusual feedstock.”

The compounds that company generated comprise up to 30% chewing gum waste.

Hordik said, “The compounds exhibit a low compression set. They can be formulated for either glossy or matte finishes, readily accept colors, and are recyclable.”

Bullus realized that used chewing gum was everywhere. There no single source to recycle or repurpose it existed, the inspiration for Gumdrop was born.

Engineers did various lab experiments using different materials, temperatures, and resins and came up with a moldable material. This moldable material could be used to manufacture a bin to collect and recycle gums. It comes with a key ring attached so it can be carried along with other personal items. Once the Gumdrop container is full, it can be mailed back to the company or dropped off at various collection points.

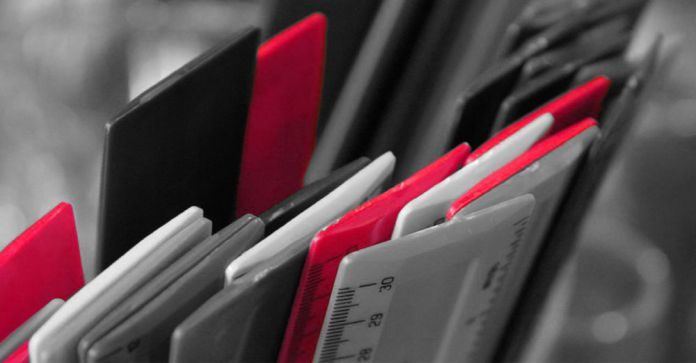

Additionally, the company has also come up with new commercial product Gumboots. Gumboots is a collection of colorful welly boots for kids and adults.

Bullus said, “Every kilogram of chewing gum that goes into a Gum-Tec compound means one less kilogram going to the landfill.”