Engineers from the UK’s Durham University and Germany’s Fraunhofer Institute have created what they say is the first manufactured “non-cuttable material.” The material, which is both highly deformable and ultra‐resistant to dynamic point loads, was named Proteus after the shape-changing Greek god of the sea.

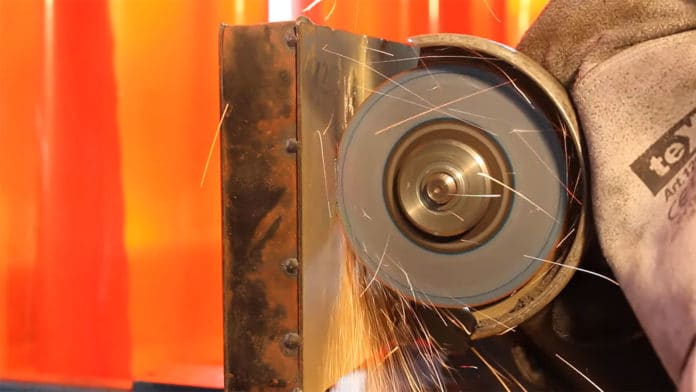

It is inspired by the tough cellular skin of the grapefruit and the fracture-resistant shells of the abalone sea creature. According to the team, the bio-inspired metallic cellular structure is non-cuttable by an angle grinder and a power drill, and it has only 15% steel density.

The Proteus could be used to make bike locks, lightweight armor, and protective equipment for people who work with cutting tools in construction and maintenance.

The non-cuttable material is made from alumina ceramic spheres encased in a cellular aluminum, metallic foam structure, and works by turning back the force of a cutting tool on itself. In tests, Proteus could not be cut by angle grinders, drills, or high-pressure water jets. The interlocking vibrational connection created by the ceramic spheres inside the casing resists the cutting disc or drill bit and turns the destructive force back in itself.

In addition, the fine particles in the ceramics fragment, which fill the cellular structure of the material, harden as the speed of the cutting tool is increased due to interatomic forces between the ceramic grains. The contrast between the ceramic segments and cellular material was also effective against a waterjet cutter because the curved surfaces of the ceramic spheres widen the jet to substantially reduces its speed and weaken its cutting capacity.

“Essentially cutting the material is like cutting through a jelly-filled with nuggets – if you get through the jelly, you hit the nuggets, and the material vibrates in such a way that it destroys the cutting disc or drill bit,” the scientist wrote in a statement.

The team has a patent pending for their non-cuttable material technology and is hoping to work with industry partners so it can be mass-produced, as there is no shortage of the metals and ceramics it is made from.

Journal Reference:

- Non-cuttable material created through local resonance and strain rate effects. DOI: 10.1038/s41598-020-65976-0