MIT specialists have created equipment that uses electric fields to move beads of a compound or natural arrangements around a surface, blending them in ways that could be utilized to test a large number of responses in parallel.

The specialists see their framework as a contrasting option to the microfluidic gadgets now generally utilized as a part of a natural research, in which organic arrangements are pumped through minuscule channels associated with mechanical valves. The new approach, which moves arrangements around in computationally endorsed designs, could empower tests to be directed all the more productively, cost-viably, and at bigger scales.

With this new framework, a huge number of beads could be saved on the surface of his gadget, and they would naturally move around to complete organic investigations.

The framework incorporates programming that enables clients to depict, at an abnormal state of a sweeping statement, the examinations they wish to lead. The product at that point naturally ascertains beads’ ways over the surface and arranges the planning of progressive operations.

Udayan Umapathi, a researcher at the MIT Media Lab said, “Traditional microfluidic systems use tubes, valves, and pumps. What this means is that they are mechanical, and they break down all the time. I noticed this problem three years ago when I was at a synthetic biology company where I built some of these microfluidic systems and mechanical machines that interact with them. I had to babysit these machines to make sure they didn’t explode.”

“Biology is moving toward more and more complex processes, and we need technologies to manipulate smaller and smaller-volume droplets. Pumps, valves, and tubes quickly become complicated. In the machine that I built, it took me a week to assemble 100 connections. Let’s say you go from a scale of 100 connections to a machine with a million connections. You’re not going to be able to manually assemble that.”

In the previous 10 years, other research bunches have explored different avenues regarding “computerized microfluidics,” or electrical control of beads, to lead organic tests. Yet, their chips were made utilizing top of the line drawing methods that require controlled conditions known as perfect rooms. Umapathi and his partners have concentrated on getting costs down. Their model uses a printed circuit board, a printed electronic gadget that comprises of a plastic board with copper wiring kept over it.

The analysts’ main specialized test was to plan a covering for the surface of the circuit board that would lessen grating, empowering beads to slide crosswise over it, and that would keep natural or concoction atoms from adhering to it, so they won’t debase future investigations.

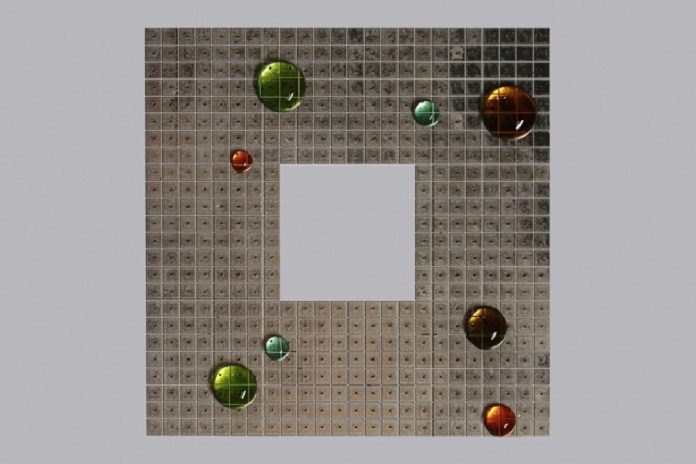

The circuit board is designed with a variety of terminals. In the model, the analysts coat the board with a substantially denser cluster of little circles, just a micrometer high, produced using a hydrophobic (water-repellent) material. Beads skate over the highest points of the circles. The specialists are additionally exploring different avenues regarding structures other than circles, which may work better with specific natural materials.

Since the gadget’s surface is hydrophobic, beads saved on it normally attempt to accept a round shape. Charging a cathode pulls the bead descending, straightening it out. In the event that the cathode underneath a leveled bead is progressively killed, while the anode alongside it is slowly turned on, the hydrophobic material will drive the bead toward the charged terminal.

Moving beads requires high voltages, somewhere close to 95 and 200 volts. However, 300 times each second, a charged cathode in the MIT analysts’ gadget interchanges between a high-voltage, low-recurrence (1-kilohertz) flag, and a 3.3-volt high-recurrence (200-kilohertz) flag. The high-recurrence flag empowers the framework to decide a bead’s area, utilizing basically a similar innovation that touch-screen telephones do.

On the off chance that the bead isn’t moving quickly enough, the framework will naturally support the voltage of the low-recurrence flag. From the sensor flag, the framework can likewise appraise a bead’s volume, which, together with area data, enables it to track a response’s advance.

Umapathi trusts that computerized microfluidics could definitely cut the cost of exploratory systems basic in modern science. Pharmaceutical organizations, for example, will often direct many tests in parallel, utilizing robots outfitted with handfuls or even several pipettes, small estimating tubes that are somewhat similar to lengthened eye droppers.

Umapathi said, “If you look at drug discovery companies, one pipetting robot uses a million pipette tips in one week. That is part of what is driving the cost of creating new drugs. I’m starting to develop some liquid assays that could reduce the number of pipetting operations 100-fold.”

Charles Fracchia, founder, and CEO of BioBright said, “In the last 15, 20 years, the general trend in pharma has been to move toward smaller volumes because they have greater multiplexing capability. When it comes to digital microfluidics the way Udayan does it, it’s effectively a cheaper version, and it’s one-sided instead of being sandwiched between two electrodes. I don’t want to call it DIY bio, but it’s lower-cost, simpler instrumentation, easier access. He definitely hit that note a lot better than [earlier systems] did. It’s exciting that he’s managed to do it with lower voltage, and it’s exciting that he can do it with a single electrode.”