Since the invention of X-rays, there has been a lot of progress. Today’s X-ray medical uses include fluoroscopy, radiotherapy for cancer, and computer tomography (CT), which takes multiple X-ray scans of the body from different angles and then combines them in a computer to generate virtual cross-sectional “slices” of a body.

In any case, medical imaging regularly works with low-exposure conditions and accordingly requires cost-effective, high-resolution detectors that can operate at what is known as a “low photon flux”. Photon flux depicts the number of photons that hit the detector at a given time and decides the quantity of electrons it produces.

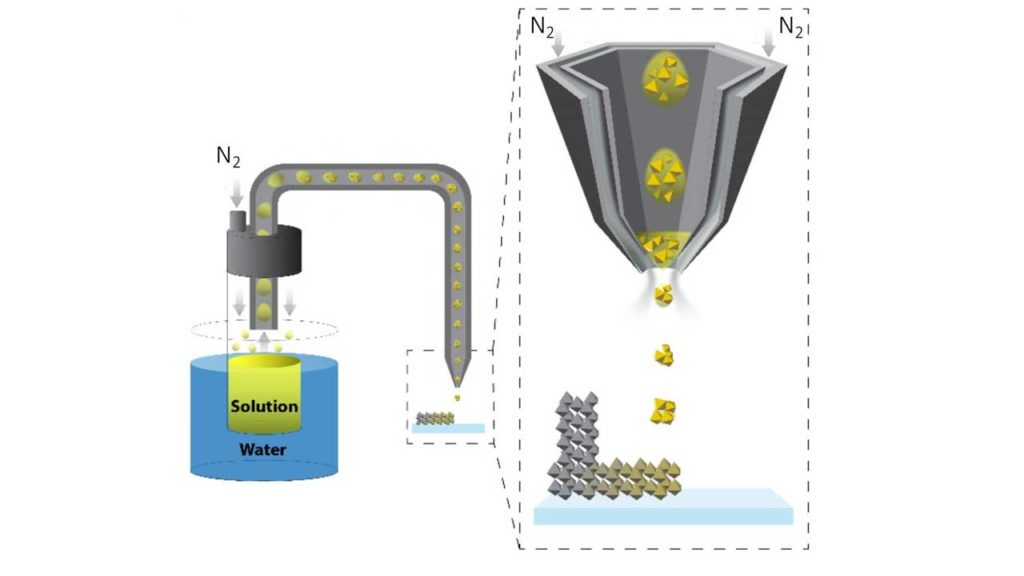

Now, EPFL scientists led by László Forró at the School of Basic Sciences have developed exactly such a device unit. Using 3D aerosol jet-printing, they developed X-ray detectors with record sensitivity to significantly improve efficiency and reduce medical imaging devices’ costs and health hazards.

Scientists developed these detectors using graphene and perovskites. Both materials are versatile, easy to synthesize, and at the forefront of a wide range of applications, including solar cells, LED lights, lasers, and photodetectors.

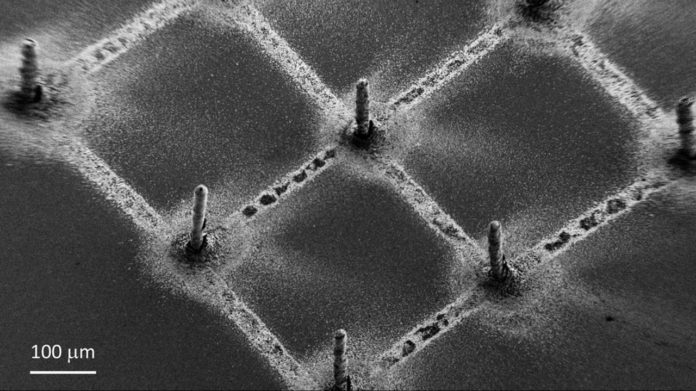

Here, an aerosol jet printing device was used to 3D print perovskite layers on a graphene substrate. The thought is that, in a gadget, the perovskite goes about as the photon detector and electron discharger while the graphene intensifies the outgoing electrical signal.

Scientists mainly used the methylammonium lead iodide perovskite (MAPbI3). This perovskite has heavy atoms, which provide a high scattering cross-section for photons, making this material a perfect candidate for X-ray detection.

Endre Horváth, the research team’s chemist, said, “The results were stunning. The method produced X-ray detectors with record sensitivity and a four-fold improvement on the best-in-class medical imaging devices.”

Forro said, “By using photovoltaic perovskites with graphene, the response to X-rays has increased tremendously. This means that if we would use these modules in X-ray imaging, the required X-ray dose for forming an image could be decreased by more than a thousand times, decreasing the health hazard of this high-energy ionizing radiation to humans.”

“Another advantage of the perovskite-graphene detector is that it is simple to form images using it. It doesn’t need sophisticated photomultipliers or complex electronics. This could be a real advantage for developing countries.”

Journal Reference:

- Anastasiia Glushkova et al. Ultrasensitive 3D Aerosol-Jet-Printed Perovskite X‑ray Photodetector ACS Nano 17 February 2021. DOI: 10.1021/acsnano.0c07993