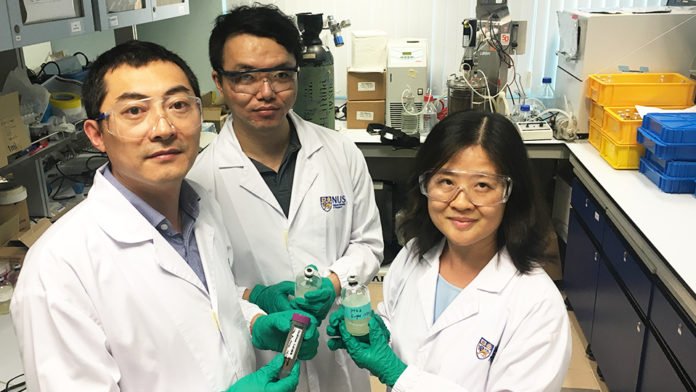

Scientists at the National University of Singapore (NUS) have developed a new technique for biofuel production by discovering that a naturally occurring bacterium, Thermoanaerobacterium thermosaccharolyticum TG57, isolated from waste generated after harvesting mushrooms, is capable of directly converting cellulose, a plant-based material, to biobutanol.

Scientists actually discovered the novel TG57 strain in 2015. They went ahead to culture the strain to analyze its properties.

Biofuels created from natural cellulosic materials, for example, plant biomass, and agribusiness, agricultural and natural waste, are required to meet developing vitality requests without expanding ozone-depleting substance discharges coming about because of the copying of petroleum products. These cellulosic materials are of incredible wealth, earth amicable, and financially reasonable.

Among different kinds of biofuels, biobutanol offers an awesome guarantee as petroleum substitute in view of its high vitality thickness and prevalent properties. It can straightforwardly supplant gas in auto motors with no change. Be that as it may, the business creation of biobutanol has been hampered by the absence of strong microorganisms equipped for changing over cellulosic biomass into biofuels. The present strategy is exorbitant and furthermore requires convoluted substance pre-treatment.

Assoc Prof He explained, “The production of biofuels using non-food feedstocks can improve sustainability and reduce costs greatly. In our study, we demonstrated a novel method of directly converting cellulose to biobutanol using the novel TG57 strain. This is a major breakthrough in metabolic engineering and exhibits a foundational milestone in the sustainable and cost-effective production of renewable biofuels and chemicals.”

This novel technique could potentially be a game-changing technology for cost-effective and sustainable biofuel production. Spent mushroom compost – normally made out of wheat straw and saw clean – is the lingering fertilizer squander produced by mushroom cultivating. The microorganisms in the waste are left to develop normally for over two years to acquire the one of a kind TG57 strain.

The aging procedure is basic, and no confounded pre-treatment or hereditary change of the microorganisms is required. At the point when cellulose is included, the bacterium just processes it to deliver butanol as the primary item.

Pushing ahead, the examination group will keep on optimizing the execution of the TG57 strain, and further designer it to upgrade biobutanol proportion and yield utilizing sub-atomic hereditary devices.

The team published the findings of the study in the scientific journal Science Advances on 23 March 2018.