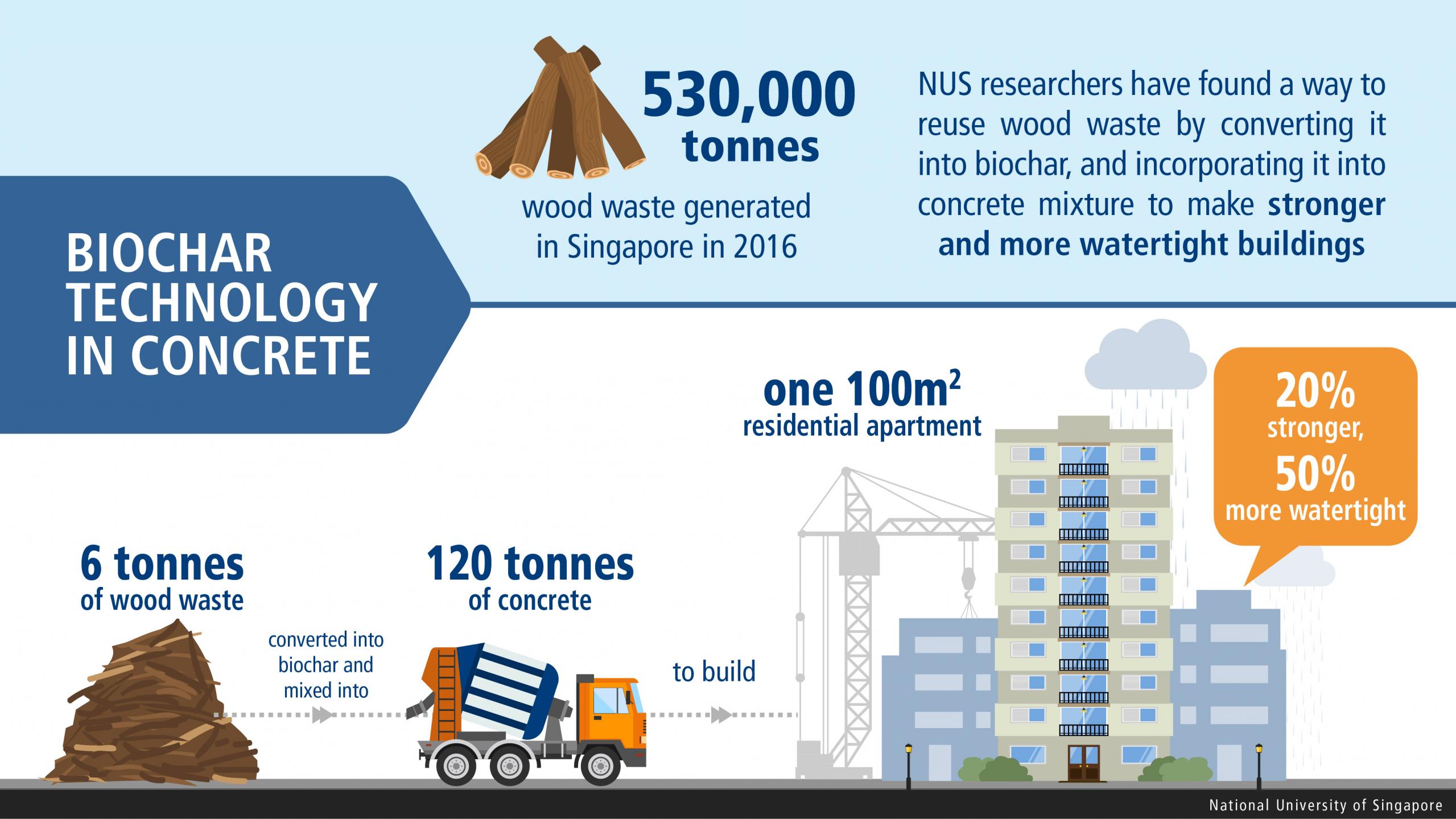

Wood waste from furniture processing plants makes up a tremendous segment of waste produced in Singapore. In 2016 alone, in excess of 530,000 tons of wood squander were created, of which, a critical sum is as observed tidy. Rather than burning or arranging them in landfills, wood waste can be reused to make biochar, a permeable, carbon-rich material that assimilates and holds water well.

Scientists from the National University of Singapore (NUS) have discovered a creative and ecological cordial system to improve building structures. The new strategy, which consolidates biochar reused from saw tidy into bond, enhances the quality and water snugness of mortar and cement, and offers an elective use to the vast volume of wood waste delivered.

Biochar is largely employed in the agricultural industry as a soil amendment to improve crop yield. Scientists expanded the application of biochar by successfully using biochar recycled from sawdust to significantly improve the mechanical and permeability properties of concrete and mortar.

During experiments, scientists added a small amount of dry biochar powder into the concrete or mortar mixture. Doing this alters the conditions in the blend and improves the curing and solidifying of the blend.

The improvement in early strength and impermeability of the concrete and mortar mixture can reach up to 20% and 50% respectively. This can encourage early evacuation of formwork, which significantly spares development time and cost. Moreover, biochar itself ‘secures’ carbon in its structure, which would some way or another be discharged to the climate by rot or by cremation of biomass.

The utilization of the biochar innovation in solid development is subsequently a novel and creative approach to store carbon in structures while advancing reusing of wood waste and reinforcing building structures.

Associate Professor Kua Harn Wei said, “This is a simple and affordable strategy to enhance our building structures, particularly in Singapore, where water leakage from rain and water pipes are common problems. At the same time, we are putting a large amount of wood waste generated in Singapore into good use.”

“Close to 50 kilograms of wood waste can be utilized for every tonne of concrete fabricated. We typically require 0.5 cubic meters of concrete for every square meter of floor area built in Singapore. This translates to around six tonnes of wood waste being recycled to build a typical 4-room HDB unit with a floor area of 100 square meters.”

The team includes Professor Kua, his Ph.D. student, Mr. Souradeep Gupta and scientists from the Department of Building at NUS School of Design and Environment.