The overall mission by scientists to discover better, more proficient materials for tomorrow’s sun based boards is normally moderate and meticulous. Scientists regularly should create lab tests — which are frequently made out of various layers of various materials reinforced together — for broad testing.

Now, MIT scientists concoct an approach to sidestep such costly and tedious manufacture and testing, taking into consideration a fast screening of much a bigger number of varieties that would be down to earth through the customary approach.

Traditional methods often require making a specialized sample, but that differs from an actual cell and may not be fully representative of a real solar cell’s performance. Unlike that, this new process could not only speed up the search for new formulations but also do a more accurate job of predicting their performance.

Rachel Kurchin, an MIT graduate student said, “Typical testing methods show the behavior of the “majority carriers,” the predominant particles or vacancies whose movement produces an electric current through a material. But in the case of photovoltaic (PV) materials, it is actually the minority carriers — those that are far less abundant in the material — that are the limiting factor in a device’s overall efficiency, and those are much more difficult to measure.”

“Moreover, those procedures only measure the flow of current in one set of directions — within the plane of a thin-film material — whereas it’s up-down flow that is actually harnessed in a working solar cell. In many materials, that flow can be “drastically different,” making it critical to understand in order to properly characterize the material.”

Historically, the rate of new materials development is slow — typically 10 to 25 years. One of the things that makes the process slow is the long time it takes to troubleshoot early-stage prototype devices. Performing characterization takes time — sometimes weeks or months — and the measurements do not always have the necessary sensitivity to determine the root cause of any problems.

Tonio Buonassisi, an associate professor explained, “If we want to accelerate the pace of new materials development, it is imperative that we figure out faster and more accurate ways to troubleshoot our early-stage materials and prototype devices.”

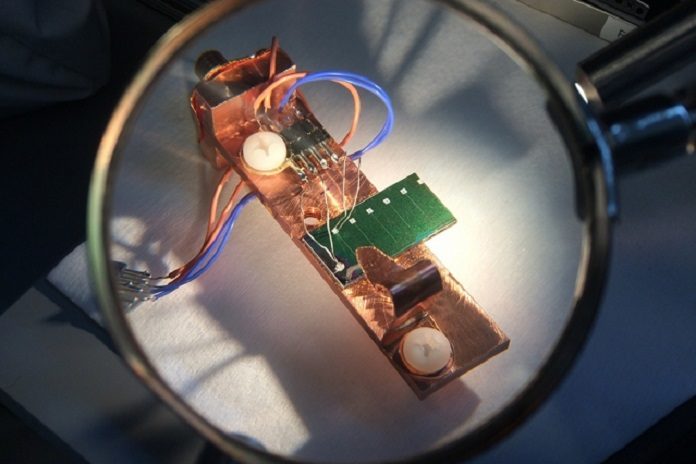

This is what the scientists had achieved. They have built up a set of apparatuses that can be utilized to make exact, fast appraisals of proposed materials, utilizing a progression of moderately basic lab tests joined with PC demonstrating of the physical properties of the material itself, and extra displaying in light of a factual technique known as a Bayesian deduction.

The framework includes making a basic test gadget, at that point measuring its present yield under various levels of enlightenment and diverse voltages, to evaluate precisely how the execution differs under these evolving conditions. These qualities are then used to refine the factual model.

Buonassisi explained, “After we acquire many current-voltage measurements [of the sample] at different temperatures and illumination intensities, we need to figure out what combination of materials and interface variables make the best fit with our set of measurements.”

“Representing each parameter as a probability distribution allows us to account for experimental uncertainty, and it also allows us to suss out which parameters are covarying.”

The procedure enables the appraisals of every parameter to be refreshed in light of each new estimation, steadily refining the assessments and homing in nearer and nearer to the exact answer. In looking for a blend of materials for a specific sort of use. Putting every one of these materials properties and interface properties, and it will reveal what the yield will resemble.

Kurchin said, “The system is simple enough that, even for materials that have been less well-characterized in the lab. We’re still able to run this without tremendous computer overhead. Making use of the computational tools to screen possible materials will be increasingly useful because “lab equipment has gotten more expensive, and computers have gotten cheaper. This method allows you to minimize your use of complicated lab equipment.”

Buonassisi said, “The basic methodology. It could be applied to a wide variety of different materials evaluations, not just solar cells — in fact, it may apply to any system that involves a computer model for the output of an experimental measurement.”

“For example, this approach excels in figuring out which material or interface property might be limiting performance, even for complex stacks of materials like batteries, thermoelectric devices, or composites used in tennis shoes or airplane wings. And, it is especially useful for early-stage research, where many things might be going wrong at once.”

“Our vision is to link up this fast characterization method with the faster materials and device synthesis methods we’ve developed in our lab. Ultimately, I’m very hopeful the combination of high-throughput computing, automation, and machine learning will help us accelerate the rate of novel materials development by more than a factor of five. This could be transformative, bringing the timelines for new materials-science discoveries down from 20 years to about three to five years.”