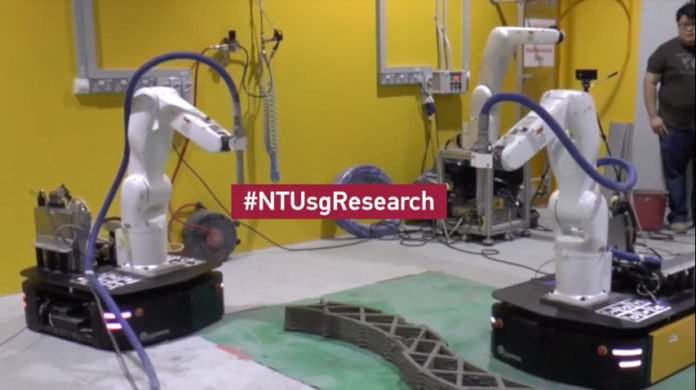

Scientists at the Nanyang Technological University, Singapore (NTU Singapore) have come up with a new technology that allows two robots to work simultaneously to 3D-print a concrete structure. This new multi-robot technology will allow for unique concrete designs currently not possible with conventional casting.

Also known as swarm printing, the technology could potentially lead to mobile robots to print even bigger structures in the future.

Having multiple mobile robots that would 3d print in sync implies expansive structures like architectural features and exceptionally planned exteriors can be printed anyplace insofar as there is sufficient space for the robots to move around the work site.

The NTU robots 3D-printed a concrete structure measuring 1.86m x 0.46m x 0.13m in eight minutes. It took two days to harden and one week for it to achieve its full strength before it was ready for installation.

Developed by Assistant Professor Pham Quang Cuong and his team at NTU’s Singapore Centre for 3D Printing, this new multi-robot technology was published in Automation in Construction, a top-tier journal for civil engineering.

Assistant Professor Pham Quang Cuong said, “We envisioned a team of robots which can be transported to a work site, print large pieces of concrete structures and then move on to the next project once the parts have been printed.”

“This research builds on the knowledge we have acquired from developing a robot to autonomously assemble an Ikea chair. But this latest project is more complex in terms of planning, execution, and on a much larger scale.”

This multi-step process begins by having the computer map outline to be printed and assign a specific piece of the printing to a robot. It at that point utilizes a unique calculation to guarantee that every one of robot arm won’t slam into another amid the simultaneous printing.

Utilizing exact area positioning, the robots at that point move into place and print the parts in a good alignment, guaranteeing that the joints between the different parts are covered. At long last, the mixing and pumping of the specific liquid concrete must be mixed equally and synchronized to ensure consistency.

Professor Chua Chee Kai, Executive Director of the Singapore Centre for 3D Printing said disruptive Industry 4.0 technologies like additive manufacturing, can be advanced even further when combined with other innovative technologies like robotics, AI, materials science and green manufacturing techniques.

“This multiple robot printing projects is highly interdisciplinary, requiring roboticists to work with materials scientists to make printable concrete. To achieve the end result of a strong concrete structure, we had to combine their expertise with mechanical engineers and civil engineering experts.”

“Such an innovation demonstrates to the industry what is feasible now, and prove what is possible in the future if we are creative in developing new technologies to augment conventional building and construction methods.”