Metal-organic frameworks (MOFs) can revolutionize catalysis and functional materials design due to their reticular nature and well-defined, isolated metal sites. To meet numerous design criteria, extensive research on MOFs need to be carried out for each application.

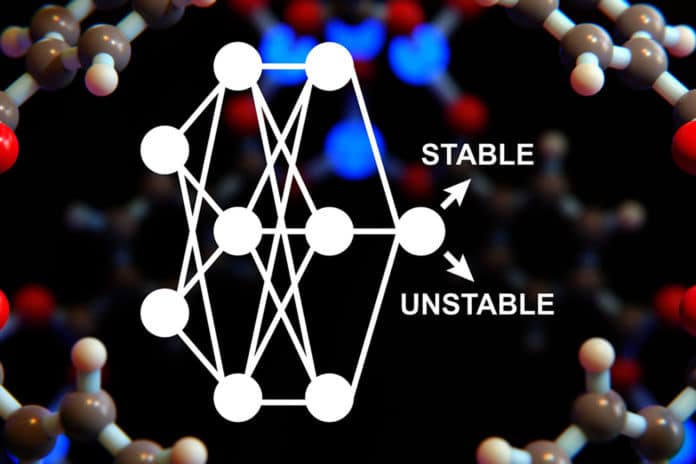

To help analyze all possible MOFs structures and help identify the best one for a particular application, MIT scientists have devised a computational model. The model analyzes the features of a MOF structure and predicts if it will be stable enough to be useful. These predictions are expected to reduce the development time of new MOFs. Plus, the model will help scientists to determine the potency of specific materials before facing the trouble of synthesizing them.

Scientists are now developing MOFs to harness methane gas and convert it to valuable compounds such as fuels.

This new computational approach is more systematic at analyzing and classifying the properties of MOFs.

Heather Kulik, an associate professor of chemical engineering at MIT, said, “When people make these now, it’s mostly trial and error. The MOF dataset is promising because so many people are excited about MOFs, so there’s so much to learn from what everyone’s been working on. Still, at the same time, it’s very noisy, and it’s not systematic the way it’s reported.”

Scientists used a natural-language-processing algorithm to analyze published reports of MOF structures and properties. Through this algorithm, scientists were able to scour through nearly 4,000 published papers, extracting information on the temperature at which a given MOF would break down. They also obtained data on whether particular MOFs can withstand the conditions needed to remove solvents used to synthesize them and make sure they become porous.

Scientists used this information to train two neural networks. Based on the molecules ‘ structure, these networks predicted MOFs’ thermal stability and stability during solvent removal.

The model allowed scientists to classify certain features that influence stability. In general, simpler linkers with fewer chemical groups are more stable. Pore size is also essential: MOFs with larger pores were too unstable. Although, scientists found that large-pore MOFs can be stable if other aspects of their structure counteract the large pore size.

Nandy said, “Since MOFs have so many things that can vary at the same time, such as the metal, the linkers, the connectivity, and the pore size, it is difficult to nail down what governs stability across different families of MOFs. Our models enable researchers to make predictions on existing or new materials, many of which have yet to be made.”

Scientists made their data and models available online.

Journal Reference:

- Aditya Nandy, Chenru Duan, and Heather J. Kulik* et al. Using Machine Learning and Data Mining to Leverage Community Knowledge for the Engineering of Stable Metal-Organic Frameworks. DOI: 10.1021/jacs.1c07217