To what extent can tiny gears and other microscopic moving parts last before they destroy? What are the warning signs that these segments are about to fail, which can occur in only a couple of tenths of a second?

To provide simple and straightforward answers, NIST scientists have devised a method to quickly track microelectromechanical systems (MEMS) as they work and, just as importantly, as they stop working. Using this method, scientists could enhance the reliability of the MEMS components that they are creating, going from small-scale robots and automatons to minor forceps for eye surgery and sensors to distinguish the number of toxic chemicals.

In their earlier work, scientists quantified the motion and interactions between MEMS components. In this new study, scientists successfully made these measurements a hundred times faster, on the scale of thousandths, rather than tenths, of a second.

Doing this enabled scientists to resolve fine details of the transient and erratic motions that may occur before and during MEMS failure. And due to quick tracking, scientists were able to do repetitive testing to assess the miniature mechanical systems’ durability.

Using optical microscopes and sensitive cameras to view an image of the light-emitting particles, the researchers tracked displacements as small as a few billionths of a meter and rotations as tiny as several millionths of a radian. One microradian is the angle corresponding to an arc of about 10 meters along the earth’s circumference.

A faster imaging system and larger fluorescent particles, which emit more light, provided the scientists with the tools to perform their particle-tracking measurements a hundred times more rapidly than before.

Craig Copeland said, “If you cannot measure how the components of a MEMS move at the relevant length and time scales, then it is difficult to understand how they work and how to improve them.”

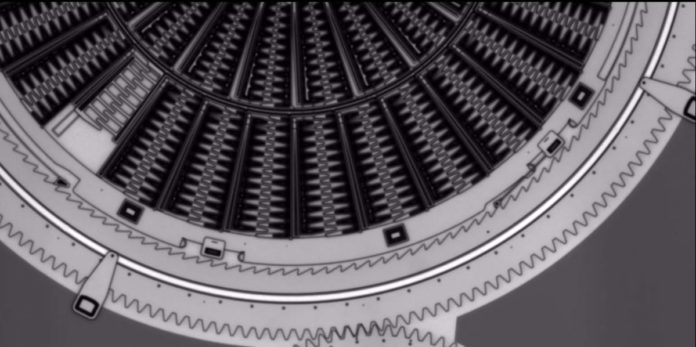

During testing, scientists tested part of a microelectromechanical motor. The test part snapped back and forth, rotating a gear through a ratchet mechanism. Although this system is a more reliable MEMS that transfers motion through parts in sliding contact, it can exhibit such problems as erratic performance and untimely failure.

Doing such, scientists found that the jostling of contacting parts in the system, whether contact between the parts occurred at only one point or shifted between several points, and wear of the contacting surfaces, could all play a key role in the durability of MEMS.

Stavis said, “Our tracking method is broadly applicable to study the motion of microsystems, and we continue to advance it.”

The study is published in the Journal of Microelectromechanical Systems.