Contemplating the chief concerns of climate protection and the reduction of carbon dioxide emissions across the globe, numerous research and development projects have been conducted on a national and international level. The objective of projects is to improve the CO2 footprint in diverse processes.

Apart from energy-intensive sectors of the industry, the building sector, in particular, is among the biggest CO2-emitters comprising from residential homes, manufacturing facilities, and storage depots to big commercial buildings. Even about 40 percent of the energy consumption within the EU is due to the heating, cooling, air conditioning, and lighting of buildings.

Bearing next-generation smart windows and façade devices in mind, one aspect of this problem is addressed in the research project Large-Area Fluidic Windows (LaWin) which has been coordinated at the Friedrich Schiller University Jena, Germany, since 2015.

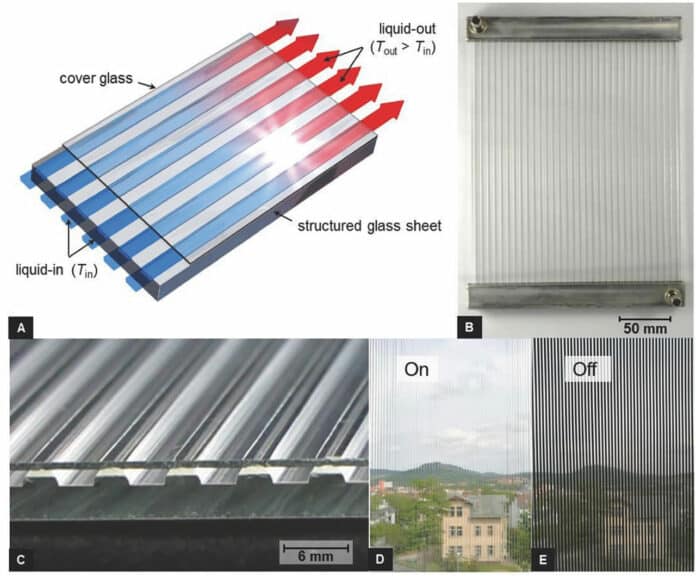

A new type of such smart windows was now presented in the upcoming issue of ‘Advanced Sustainable Systems’. In their paper ‘Large-Area Smart Window with Tunable Shading and Solar-Thermal Harvesting Ability Based on Remote Switching of a Magneto-Active Liquid,’ the Jena materials researchers introduce prototypes of a window that changes its light permeability at the touch of a button, and, at the same time, can be used for solar-thermal energy harvesting.

Lothar Wondraczek, the project’s coordinator, explains, “Our project’s key feature is the use of liquids in windows and façades, for example, as heat carriers or to enable additional functions.”

“To this end, we develop new glass materials into which large-area channel structures are integrated. These are used for circulating functional fluids.

In the latest prototypes, the liquid is loaded with nanoscale magnetic iron particles that can be extracted from the liquid with the help of a magnet. Vice versa, they can be re-suspended by simply switching off the magnet.

Wondraczek further explains, “Depending on the number of the iron particles in the liquid, the liquid itself takes on different shades of grey, or it will even turn completely black.”

“Then, it becomes possible to automatically adjust the incidence of light or to harvest solar heat, which can then be put to further use within the building.”

The efficiency of heat gain per area is comparable with that of state-of-the-art solar thermal facilities. But unlike those, the present system can be readily integrated in a vertical façade. Switching between on and off the release or capture of particles happens in a separate tank. An electrical connection at the windows is not necessary.

Wondraczek, who holds the chair of Glass Chemistry at the University of Jena, stresses, “The greatest advantage of large-scale fluidic windows is that they can substitute air conditioning systems, daylight regulation systems, and for instance, warm water processing.”

Developing cost-effective large-size window glass modules is the key. On the one hand, the glass elements need to include the channels; on the other hand, they maintain their performance over the whole lifespan of the building.

Finally, they have to provide the ability for integration with standard window manufacture technologies in frames of double or triple glazing.

Presently available prototypes manufactured on a scale of around 200 square meters, the research consortium demonstrated that those requirements can be fulfilled.