In recent years, 3D printing or additive manufacturing has developed significantly and can now perform crucial roles in many applications. Designers use 3D printers to quickly produce a range of objects that include product models, jewelry, gift and novelty items, and toys. However, we still cannot fabricate more complex devices that are essentially ready to go right out of the printer.

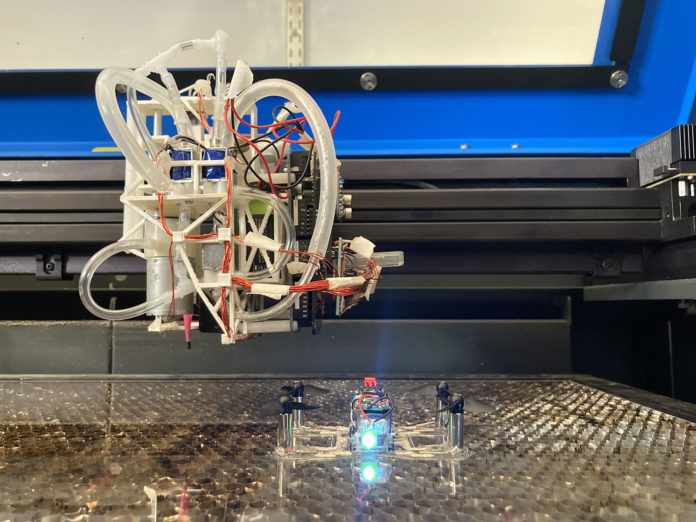

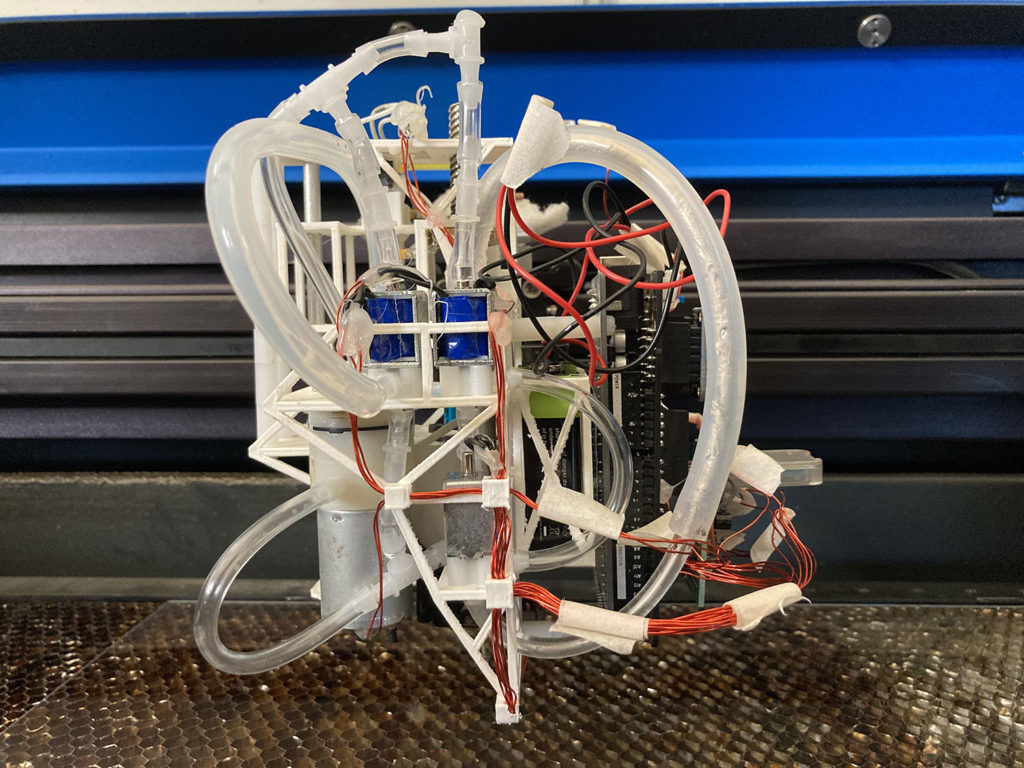

Now, a group of researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) has presented a new system to print functional, custom-made devices and robots. Called LaserFactory, the system is an electromechanical assembly and fabrication platform integrated with a laser cutter to make fully functioning devices without human intervention. The machine allows the user to not only create structural geometry but also print circuit traces, pick-and-place electronic and electromechanical components like sensors and actuators, and solder them.

The LaserFactory consists of two parts: a software toolkit that allows users to design custom devices and a hardware platform that fabricates them.

If users want to create their own device, they would first design it by placing components from a part library and drawing on circuit traces. The circuit traces are the copper or aluminum lines on a printed circuit board that allow electricity to flow between electronic components.

The software then translates their custom blueprint into machine instructions that are embedded into a single fabrication file for LaserFactory to make the device in one go. The hardware add-on to an existing laser cutter consists of a silver dispenser and pick-and-place mechanism and allows the LaserFactory to automatically cuts the geometry, dispenses silver for circuit traces, picks-and-places components. Finally, a laser soldering method is used to cure the deposited silver traces to make the traces conductive, securing the components in place to complete fabrication. After laser soldering, the fabricated device is fully functional.

“Making fabrication inexpensive, fast, and accessible to a layman remains a challenge,” says Nisser, lead author on a paper about LaserFactory that will appear in the ACM Conference on Human Factors in Computing Systems in May. “By leveraging widely available manufacturing platforms like 3-D printers and laser cutters, LaserFactory is the first system that integrates these capabilities and automates the full pipeline for making functional devices in one system.”

LaserFactory system can be used to fabricate devices such as fully functioning wearables, robots, and printed electronics. According to the researchers, the system can assemble a variety of differently sized components up to 65g.

In future work, the team hopes to increase the quality and resolution of the circuit traces, which would allow for denser and more complex electronics.

Journal Reference:

- LaserFactory: A laser cutter-based electromechanical assembly and fabrication platform for making functional devices