More accurate product labeling and traceability are required in circular supply networks. Product life cycle management in the apparel sector must be partly improved by inaccurate, poorly readable, and removable standard care labels. This study aims to enable an intrinsically recyclable, low-cost labeling method to encode information and allow quick readout after years of typical use.

An estimated 15 million tonnes of textiles are burned or end up in landfills each year in the US. This waste, which represents 85% of the fabrics made in a given year, is a significant environmental issue. Massachusetts was the first state to pass laws banning the dumping of textiles in the garbage in 2022 from increasing recycling rates.

Recycling textiles is only sometimes simple. Those cannot be resold as they are being shipped to facilities where they are categorized by fabric type. Hand sorting is time-consuming and challenging due to worn-out or missing labels. More modern approaches that study a garment’s chemistry need to be revised to identify components in fabric mixes, which comprise the majority of clothes.

A team from MIT Lincoln Laboratory and the University of Michigan offers an innovative technique to label fabrics to improve this sorting process: weaving fibers with designed reflectivity. This fiber is only reflective under specific infrared light wavelengths, allowing recyclers to determine the type of cloth the fiber represents.

To identify a product, the fiber acts like an optical barcode, and having a way to quickly identify fabric types and sort them as they come through could help recycling systems scale up.

Erin Doran, a co-author of the team’s study, said, “Having a way to easily identify fabric types and sort them as they’re coming through could help make recycling processes scale up. We want to find ways to identify materials for another use after the life cycle of the garment.”

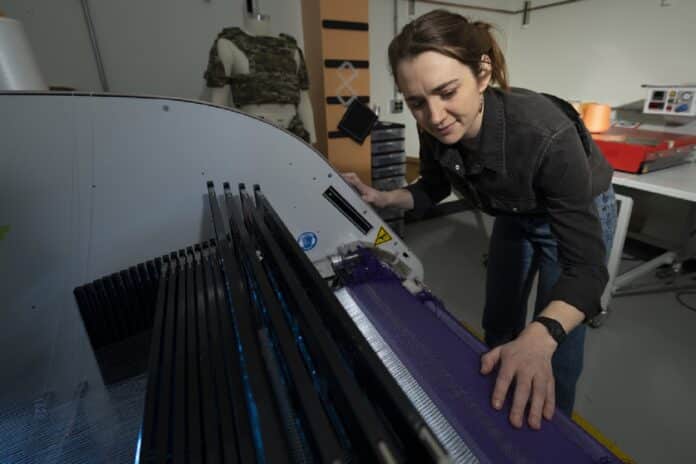

Erin Doran, a textile specialist at Lincoln Laboratory’s Defense Fabric Development Center (DFDC), is working with researchers in the Advanced Materials and Microsystems Group to create “future fabrics” by merging fibers with tiny electronics and sensors.

Brian Iezzi, the study’s lead author, is investigating ways to improve textile recyclability. His work in U-Michigan’s Shtein Lab focuses on applying photonics to fiber-based devices, such as a structural-color fiber developed at MIT by Professor Yoel Fink. It is an area of expertise at the DFDC.

He is evaluating marketing alternatives after the team applied for patent protection for their technology. The fibers generated in this study are still significantly thicker than garment fibers. Therefore further thinning while maintaining reflectivity at the required wavelengths is an ongoing field of research.

DFDC researcher Bradford Perkins, a study co-author, said, “It’s a fiber that acts like a perfect mirror. By layering certain materials, you can design this mirror to reflect specific wavelengths.

In this case, you’d want reflections at wavelengths that stand out from the optical signatures of the other materials in your fabric, which tend to be dark because common fabric materials absorb infrared radiation.

Perkins says, “Unlike the eye-catching designs of butterfly wings, the fibers are not meant to be showy. They would make up less than a few percent of the fabric. Nobody would be able to tell that they’re there until they had an infrared detector.”

The fiber starts as a block of a polymer called a preform. The team carefully constructed the preform to contain more than 50 alternating layers of acrylic and polycarbonate. It is heated and pulled like taffy to produce a fiber the same size as a conventional yarn in fabric.

The pairing of the two materials reflects and absorbs light to create an optical effect that can look like color, similar to butterfly wings.

Tairan Wang, also from Lincoln Laboratory, said, “Butterfly wings are one example of structural color in nature. When you look at them very closely, they’re really a sheath of material with nanostructured patterns that scatter light, similar to what we’re doing with the fibers.”

Researchers may “tune” the fibers to reflect and absorb particular, periodic ranges of wavelengths by controlling the speed at which the fibers are drawn, resulting in an individual optical barcode in each fiber.

The corresponding fabric types can then be given to this barcode, with one symbolizing, for example, cotton and another polyester.

According to the researchers, a detector similar to those used to classify plastics in the recycling business may be modified. Such sensors, too, use infrared sensing to identify the unique optical signatures of various polymers.

The researchers are also studying how structural-color fibers can help solve other environmental issues in the textile industry, such as toxic waste from dyes.

Doran said, “It’s important for us to consider recyclability as the electronic-textile market expands, too. This idea can open avenues for recovering chips and metals during the textile recycling process. Sustainability is a big part of the future, and it’s been exciting to collaborate on this vision.”

Journal Reference:

- Brian Iezzi, Erin Doran, etal. Polymeric Photonic Crystal Fibers for Textile Tracing and Sorting. Advanced Materials Technologies. DOI: https://doi.org/10.1002/admt.202201099