Anti-icing and icephobic materials are essential in various applications, including energy and transportation systems that operate in cold areas. Despite significant breakthroughs in creating such surface coatings, anti/de-icing chemicals are still one of the most used ice-management options. They are, however, known for being susceptible to shear forces and dissolution.

Sushant Anand, a UIC assistant professor of mechanical engineering, and Rukmava Chatterjee, a UIC Ph.D. student, have developed eco-friendly, frost-resistant, and ice-phobic coatings that are more efficient products immune to ice. Unlike conventional coatings, the newly developed coating lasts longer and benefits other industries.

Anand said, “We questioned the lifetime of the cryoprotectants and looked at new ways to increase their effectivity. Glycols dissolve very fast in the water and get washed away before the plane takes off, and it’s a serious problem that costs hundreds of millions of dollars –- most of which ends up in the drain. We thought, why not improve such chemicals themselves and make alternatives that can last longer while being more biofriendly. And that is what we ended up doing.”

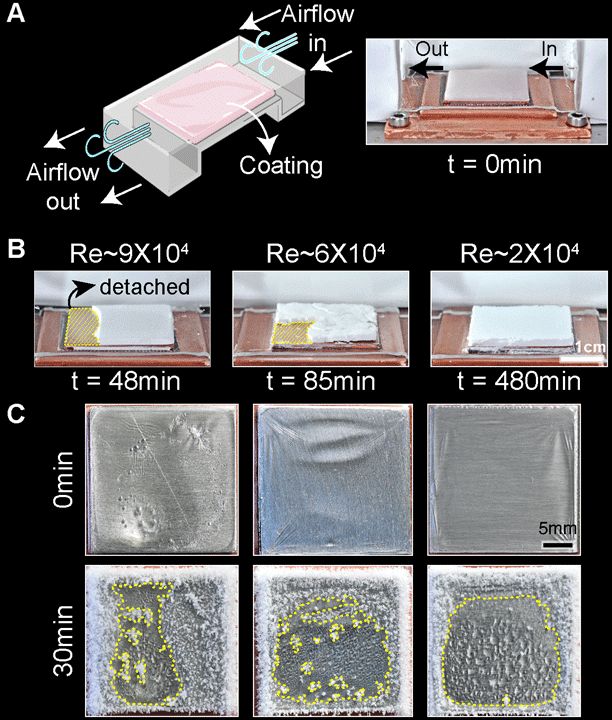

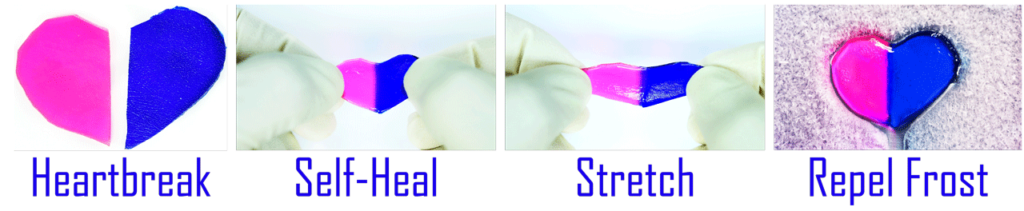

Scientists have come up with an extensive family of more than 80 anti-freezing coatings. Their coatings can be categorized according to polymeric solutions, emulsions, creams, and gels. In simple words, the coatings are an all-in-one package that can delay frost formation for extended hours. Plus, they can quickly shed off any ice formed on its surface by a gentle breeze or simple substrate tilting.

Without preconditioning or costly surface treatments, the formulations can be applied to aluminum, steel, copper, glass, plastic, or other industrial surfaces.

The newly created coatings are a group of phase transition material-based formulations and multifunctional coatings. Regardless of the underlying material composition and chemistry, these coatings can modify solid foulant adherence to functional surfaces, ranging from ice to microorganisms. This was engineered by regulating how chemicals leach out of the material system and creating a lubricating surface layer that is both slippery and non-freezing.

The anti-freezing gels are also transparent, critical for applications like traffic signals, runway lights that assist pilots during landings, automotive windshields, or building windows.

Chatterjee said, “Imagine coating your smartwatch with our gel that can inhibit ice accretion in the chilly negatives while simultaneously preventing any bacterial contamination.”

Anand said, “Since our anti-icing sprays are bio-friendly and anti-bacterial, we even think there is a potential to use them in agriculture to prevent crops from being ruined by severe frost. But that is a pipe dream, and we need to do more studies to see if there will be any long-term adverse effect on the plants.”

“There is great potential in these materials for many applications, and I think the day when commercial versions of our materials come out just got closer.”

Journal Reference:

- Rukmava Chatterjee et al. A Family of Frost-Resistant and Icephobic Coatings. DOI: 10.1002/adma.202109930