Power gadgets, which do things like adjust voltages or change over amongst immediate and exchanging current, are all over. They’re in the power blocks we use to charge our versatile gadgets; they’re in the battery packs of electric autos; and they’re in the power network itself, where they intervene between high-voltage transmission lines and the lower voltages of family unit electrical attachments.

The problem remains with power conversion as they are intrinsically inefficient. A power converter will never output quite as much power as it takes in. Still, power converters made from gallium nitride have begun to reach the market.

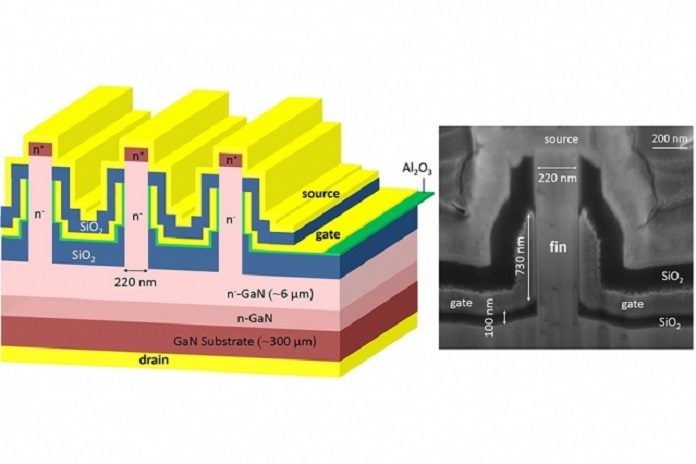

Courtesy of Yuhao Zhang

Now, MIT scientists have come up with a new invention enabled gallium nitride power devices to handle voltages of 1,200 volts.

Tomás Palacios, who is an MIT professor of electrical engineering said, “All the devices that are commercially available are what is called lateral devices. So the entire device is fabricated on the top surface of the gallium nitride wafer, which is good for low-power applications like the laptop charger. But for medium- and high-power applications, vertical devices are much better.”

“These are devices where the current, instead of flowing through the surface of the semiconductor, flows through the wafer, across the semiconductor. Vertical devices are much better in terms of how much voltage they can manage and how much current they control.”

For one thing, current flows into one surface of a vertical device and out the other. That means that there’s simply more space to which to attach input and output wires, which enables higher current loads.

Palacios explained, “For another when you have parallel gadgets, all the present moves through an exceptionally limit chunk of material near the surface. We are discussing a chunk of material that could be only 50 nanometers in thickness.”

“So all the current experiences there, and all the warmth is being created in that exceptionally limit district, so it gets ridiculously, extremely hot. In a vertical gadget, the present moves through the whole wafer, so the warmth scattering is substantially more uniform.”

However, the vertical devices have been difficult to fabricate in gallium nitride. Power hardware rely upon transistors, gadgets in which a charge connected to an “entryway” switches a semiconductor material —, for example, silicon or gallium nitride — between a conductive and a nonconductive state.

For that changing to be proficient, the present coursing through the semiconductor should be kept to a moderately little zone, where the entryway’s electric field can apply an effect on it. Previously, specialists had endeavored to assemble vertical transistors by inserting physical obstructions in the gallium nitride to coordinate current into a channel underneath the door.

In any case, the obstructions are worked from an inconsistent material that is expensive and hard to create and incorporating it with the encompassing gallium nitride in a way that doesn’t disturb the transistor’s electronic properties has additionally demonstrated testing.

Scientists adopt a simple but effective alternative. Rather than using an internal barrier to route current into a narrow region of a larger device, they simply use a narrower device. Their vertical gallium nitride transistors have bladelike protrusions on top, known as “fins.” On both sides of each fin are electrical contacts that together act as a gate.

Current enters the transistor through another contact, on top of the fin, and exits through the bottom of the device. The narrowness of the fin ensures that the gate electrode will be able to switch the transistor on and off.

Palacios said, “Instead of confining the current by having multiple materials in the same wafer, let’s confine it geometrically by removing the material from those regions where we don’t want the current to flow. Instead of doing the complicated zigzag path for the current in conventional vertical transistors, let’s change the geometry of the transistor completely.”