Paper waste, which comprises disposed paper bags, cardboard, newspaper, and other paper packaging, has a large environmental footprint compared to its counterparts made of cotton and plastic. They dramatically contribute to global warming when incinerated and the eco-toxicity potential in producing them.

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a technique to convert waste paper from single-use packaging, bags, and cardboard boxes into a crucial component of lithium-ion batteries.

The current innovation, which offers a chance to recycle waste products and lessen our reliance on fossil fuels while speeding up our transition to a circular economy, green materials, and clean energy, reflects NTU’s dedication to minimizing our impact on the environment, one of four grand challenges facing humanity that the University seeks to address through its NTU 2025 strategic plan.

Scientists used a process called carbonization to convert Paper into pure carbon. Using the process, they turned the Paper’s fibers into electrodes, which can be made into rechargeable batteries that power mobile phones, medical equipment, and electric vehicles.

Scientists then carbonized the Paper by exposing them to high temperatures. This reduces it to pure carbon, water vapor, and oils that can be used for biofuel. As carbonization occurs in the absence of oxygen and produces minimal carbon dioxide, it is a more environmentally friendly method of disposal for kraft paper than incineration, which releases many greenhouse gases.

The research team’s carbon anodes also showed improved toughness, adaptability, and electrochemical qualities. According to laboratory studies, the anodes are at least twice as robust as those in today’s phone batteries and may withstand 1,200 charges and discharges. The NTU-produced anode-based batteries could tolerate physical stress better than their rivals, absorbing up to five times better crushing energy.

What’s more, the newly developed method is less energy-intensive. It uses low-cost waste material and is also expected to bring down the cost of manufacturing them.

Assistant Professor Lai Changquan, from NTU’s School of Mechanical & Aerospace Engineering, who led the project, said: “Paper is used in many facets in our daily lives, from gift wrapping and arts and crafts, to a myriad of industrial uses, such as heavy-duty packaging, protective wrapping, and the filling of voids in construction. However, little is done to manage it when it is disposed of besides incineration, which generates high levels of carbon emissions due to their composition. Our method to give kraft Paper another lease of life, funneling it into the growing need for devices such as electric vehicles and smartphones, would help cut down on carbon emissions and ease the reliance on mining and heavy industrial methods.”

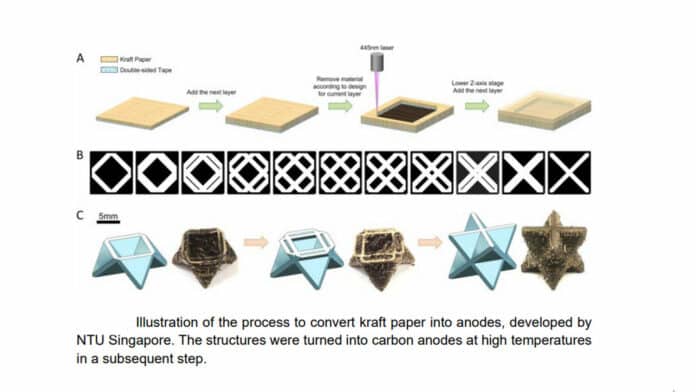

The NTU scientists connected and laser cut several thin sheets of kraft paper to create various lattice topologies, some of which resembled a spikey piata, to create the carbon anodes. The Paper was then burned to 1200 degrees Celsius in an oxygen-free furnace to transform it into carbon, making the anodes.

Co-author of the study, Mr. Lim Guo Yao, a research engineer from NTU’s School of Mechanical & Aerospace Engineering, said: “Our anodes displayed a combination of strengths, such as durability, shock absorption, electrical conductivity, which are not found in current materials. These structural and functional properties demonstrate that our kraft paper-based anodes are a sustainable and scalable alternative to current carbon materials and would find economic value in demanding, high-end, multifunctional applications, such as the nascent field of structural batteries.”

Assistant Professor Lai Changquan, from NTU’s School of Mechanical & Aerospace Engineering, who led the project, said, “Our method converts a common and ubiquitous material — Paper — into another extremely durable and in high demand. We hope that our anodes will serve the world’s quickly growing need for a sustainable and greener material for batteries, whose manufacturing and improper waste management have shown to have a negative impact on our environment.”

Highlighting the significance of the work done by the NTU research team, Professor Juan Hinestroza from the Department of Human Centered Design of Cornell University, US, who was not involved in the research, said: “As kraft paper is produced in very large quantities and disposed likewise all over the world, I believe that the creative approach pioneered by the researchers at NTU Singapore has a great potential for impact at a global scale. Any discovery that will allow the use of waste as a raw material for high-value products like electrodes and foams is indeed a great contribution. I think that this work may open a new avenue and motivate other researchers to find pathways for the transformation of other cellulose-based substrates, such as textiles and packaging materials, which are being discarded in large quantities all over the globe.”

Journal Reference:

- Chang Quan Lai, Guo Yao Lim, Kai Jie Tai, Kang Jueh Dominic Lim, Linghui Yu, Pawan K. Kanaujia, Peiyuan Ian Seetoh. Exceptional energy absorption characteristics and compressive resilience of functional carbon foams scalably and sustainably derived from additively manufactured kraft paper. Additive Manufacturing, 2022; 58: 102992 DOI: 10.1016/j.addma.2022.102992