Concrete materials are widely used manufactured materials for construction. However, the mixture leads to almost 6 percent of global carbon emissions. Still, the use of the material is rising day by day.

In the US, most of the bridges, buildings, and pavement-lined streets, were built in 1960-70 with less natural worries to the foundation and worked to most recent 50 years at most.

Now, greenhouse gas emissions.

This new approach is actually inspired by the hierarchical organization of simple building blocks in natural materials.

Courtesy of the researchers

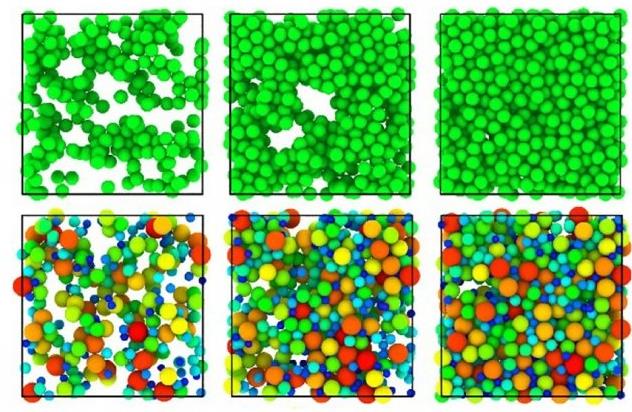

Scientists primarily observed the fundamental property of concrete solution by lining up different atoms that lead to concrete strength and durability. They used a computer model to imitate the behavior of individual atoms. They observed that the atoms are organized in such way that forms molecular building blocks within a hardening material.

According to scientists, the computer model could help designers choose local additives based on the molecular interactions of the resulting mixtures. Through careful design at the microscopic level, engineers can ultimately build stronger, more environmentally sustainable structures.

As scientists reported, the data revealed an interface within the molecular structure. This interface offers a frictional resistance under sliding deformation. By using a cohesive-frictional force model, scientists observed how these atoms interact in a larger scale.

Now scientists are identifying the ways through which the cohesive and frictional forces of groups of atoms, or colloids in cement can be improved.

Oral Buyukozturk, a professor of civil and environmental engineering said, “The conditions of the world are changing. There are increased environmental demands, including from earthquakes and floods, and stresses on infrastructure. We need to come up with materials that are sustainable, with much longer design life and better durability. That is a big challenge.”

Scientists took inspiration in part, by Roman construction. During the empire’s peak, the Romans erected temples, bath buildings, and amphitheaters by using local materials a technique that has helped preserve these structures for more than 2,000 years.

Buyukozturk said, “They probably did this through intuition. Ours is an effort to hopefully implement that kind of philosophy of using materials that are locally available, by understanding the underlying scientific principles within those materials.”

The researchers used their atomistic model to simulate mixtures containing Portland cement, the most common type of cement used in the world. Specifically, they simulated the mechanical response of the gel-like substance called calcium-silicate-hydrate (C-S-H), the main phase that forms when water reacts with Portland cement.

Modeling atom movements in building blocks influence cohesive forces that makes particles hold each other. The presence of a shear resistance as clusters of atoms slide past each other along a water-filled interface.

Identifying fundamental properties allowed them to discover the degree to which frictional properties resist the movement and separation of colloids at the mesoscale was the strongest factor in determining the strength of concrete at the centimeter scale.

Scientists thus combined their results with the computer model to compare actual, centimeter-sized laboratory experiments. They found that their predictions matched with experimental outcomes better than predictions made with simulations that neglect frictional interactions.

Sidney Yip, professor emeritus at MIT said, “The material science of concrete solution strength is still in its infancy regarding molecular-level descriptions and an ability to perform quantitative predictions. The issue of frictional force, addressed in our work, pertains to the mechanical behavior of cement that varies over time.”

“This rate sensitivity is an aspect of the scientific challenges at the mesoscale, which is the research frontier where microscale concepts and models developed in several physical science disciplines are linked to macroscale properties for technological applications.”

“We are confident that our new framework is opening a new era in concrete science.”

Scientists now are identifying the effect of such materials on the atom-to-atom behavior of cement. They will also investigate how additives influence the chemical composition of these colloidal phases.

Palkovic said, “We know relatively little of what happens when additives are used in concrete. We would not expect volcanic ash from Saudi Arabia to give the same performance as volcanic ash from Hawaii. So we need this greater understanding of the material, that starts at the atomistic scale and accounts for the chemistry of the material. That can give us greater control and understanding of how we can use additives to create a better material.”