The construction industry is the largest consumer of raw materials and records for over 33% of global energy demand. Built environments are liable for up to 40-50% of complete CO2 emanations all through their service life.

That remarkably high figure is partly due to traditional design practices applied to most civil engineering structures. Civil structures are typically designed to withstand worst-case loading events – which in practice occur very rarely: strong winds, earthquakes, snowstorms, and large crowds.

To address current environmental challenges, the construction industry must find new ways of building.

As a solution, EPFL scientists have developed new methods to design and control civil structures that can automatically adapt to loading.

Gennaro Senatore, a scientist at ENAC’s Applied Computing and Mechanics Laboratory (IMAC) and lead of the research project, said, “A solution lies in adaptive structures, which can adapt to ensure that strength and serviceability requirements are met against changing loading conditions. Adaptive structures can operate closer to design limits, which means they can perform better and in a more sustainable way than conventional passive structures.”

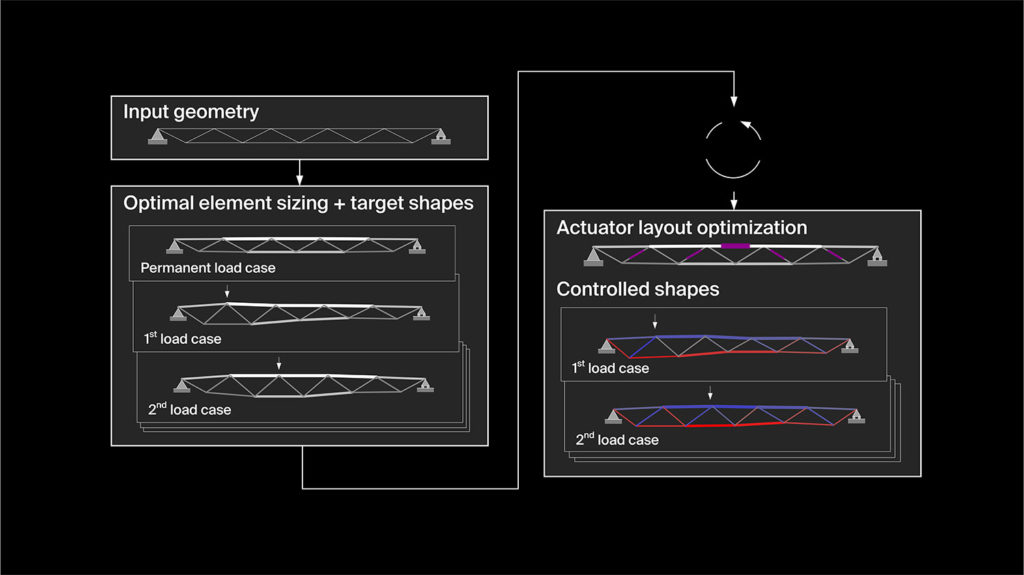

The design criterion adopted in this work is the minimization of structures’ whole-life energy requirement, including energy used for operation, for example, for sensing, control, and actuation during service, just as energy utilized for materials and construction– known as embodied energy.

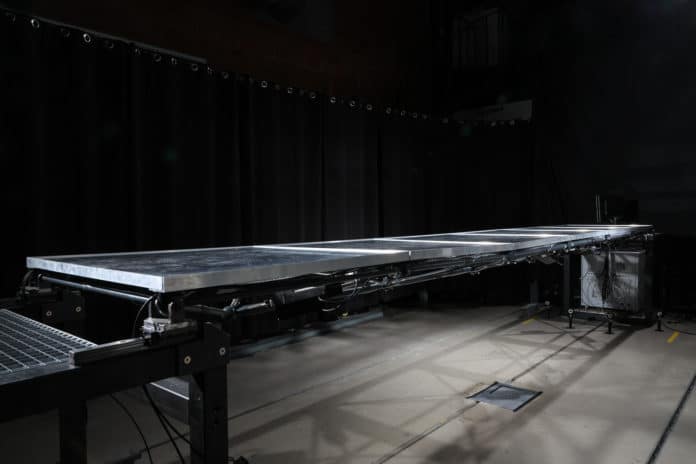

Scientists later developed a prototype to establish the feasibility of their design method and control-optimization system. The prototype can take an ordinary load passively. If the load increases above a certain activation threshold, the structure can adapt to an optimal configuration through a change of shape.

Arka Prabhata Reksowardojo, a doctoral assistant at IMAC, who successfully defended his Ph.D. thesis related to this project a few days ago, said, “The control system includes a series of sensors, control units, and actuators. Each structural element is instrumented with a strain sensor, and an optical tracking system monitors the structure movement. Machine learning has been employed to improve detection accuracy of the applied load location and intensity. The control units process information received from the sensors and command the actuators to extend a commanded act, thereby controlling the structure into an optimal shape that changes as the external load changes.”

“And what if there is a power outage? The structure would not collapse because it is designed to have sufficient load-carrying capacity even without the active system’s contribution. However, serviceability limits, such as deflections, are likely to be exceeded.”

“The footbridge is 6.6 m long, 1 m wide, and only 160 cm deep. It has a very slender configuration with a span-to-depth-ratio that is three times as high as conventional structures. This ratio indicates how a passive structure behaves under loading. The higher the ratio, the more the structure will deform – like a plastic ruler that bends in our hands. Instead, the ability to reduce deflections through active control enables a new type of structures such as super-slender adaptive buildings and bridges.”

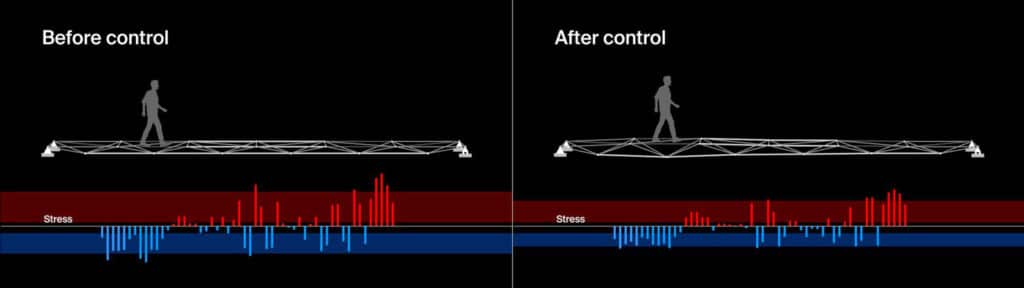

“The structure has been designed to be able to counteract the effects of loading through shape control. Part of what makes the IMAC structure innovative is that it can adapt to loading through large shape reconfigurations. This kind of structural adaptation leads to a homogenization of stress under strong loading events, with a substantial decrease (up to 37%) in the average stress between non-controlled and controlled states. Thus, the structure requires a smaller mass and embodied energy owing to the capability to change shape under loading.”

“Studies have shown that structures produced by this method achieve up to 70% embodied energy savings at the expense of a certain amount of operational energy. The deferral of energy usage obtained by replacing a large embodied share with a smaller operational share helps to reduce greenhouse gas emissions further – because the carbon footprint of energy production is likely to decrease in the future owing to technological advancements.”

“This combination of low energy requirement and super-slender design is unique in structural engineering, thereby creating high impact potential for the built environment and society as a whole.”