The announcement of airless tires or non-pneumatic tire for the passenger vehicle market sparked the interest of many drivers. However, this prototype is still being developed; the future looks bright for this revolutionary tire.

Finding a design that offsets puncture-free strength with the versatility required for a comfortable, shock-free ride like conventional pneumatic tires is the key.

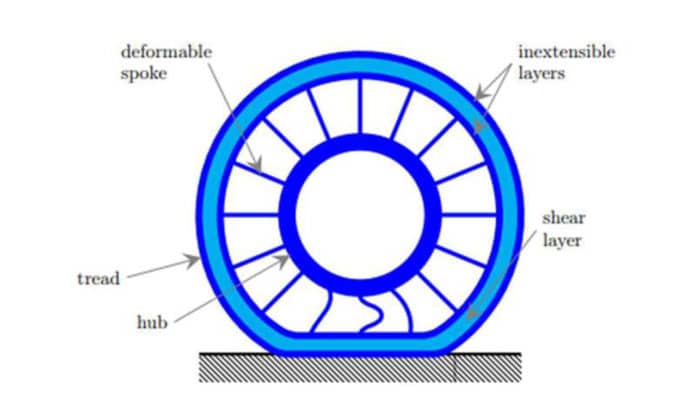

The University of Illinois specialists looking at ways they could design a puncture-proof tire that still had enough give to provide a shock-free ride. They are focusing on the tire’s shear layer, which is just below the tread in a non-pneumatic tire.

By using design optimization, scientists come up with several structural patterns for the shear layer of a non-pneumatic tire. The design optimization is a computer simulation that modeled the elastic response on the shear layer. The simulation calculates the material’s ability to stretch and twist.

Kai James, assistant professor in the Department of Aerospace Engineering at U of I, said, “We were looking for a high level of shear—that is, how much strain the material can take under pressure—but we want stiffness in the axial direction.”

“These physical pressures are not like aging or weathering on the tire, but about internal pressure and stresses—essentially, how much pressure the material exerts on itself. Beyond a certain level of stress, the material is going to fail. So we incorporate stress constraints, ensuring that whatever the design happens to be, the stress doesn’t exceed the limit of the design material.”

“Depending on how you weight each of the design requirements—buckling, stress, stiffness, shear, and every combination of those—will result in a different design. The goal is a tire design that can withstand pressure but is also elastic to provide a ride that doesn’t feel like you’re driving on tires made of steel.”

As the computer simulation attempts to find the optimum pattern, it dispenses with structural patterns that are not optimal. It starts with a computer-simulated block of the bulk material that the tire will be made from. Since a solid block doesn’t have a lot of versatility, the content is virtually cut away, leaving spaces for adaptability.

James said, “If you carve holes in the material until it is something like a checkerboard pattern, with half of the material, you’d also have half of the original stiffness. Now, if you make a much more complicated pattern, you can tailor the stiffness.”

“Obviously, on a continuum from a block of material to a thin, lacelike pattern, the number of potential designs is infinite, but it’s not realistic to test every design. And, it’s important to note that the algorithm doesn’t end by spitting out a single, optimal design.”

“Search algorithms have clever ways to strategically search the design space so that ultimately you end up having to test a few different designs as possible. Then, as you test the designs, gradually, each new design is an improvement on the previous one and, eventually, a near-optimal design.”

“The computer modeling of a structure like this one, or any physical system has levels of complexity encoded into the model—a higher accuracy model with higher fidelity is more costly.”

“From a computational standpoint, we’re generally talking about the time it takes to run the analysis on high-powered computers.”

The study is published in the International Journal for Numerical Methods in Engineering.